Johannes von Borries, managing partner of existing investor UVC Partners said: “STABL solves two important problems for the energy transition: first, the unique technology enables to build very efficient and cheap storage systems. Second, old batteries from cars are made reusable, thus extending their lifetime by many years in the spirit of the circular economy.”

The company describes its second-life BESS as a “simple and risk-free” solution for the commercial and industrial (C&I), real estate and agricultural sectors.

CEO Dr Nam Truong gave Energy-Storage.news more details on how the company sets itself apart from others in the second life space: “Our proprietary battery management system (BMS) is compatible with all battery modules with up to 18 cells in series. Our core-technology is the battery inverter that has the highest efficiency in the market and has the big advantage that we can use the full available capacity of every battery module, instead of being limited by the weakest battery module (which is always the case, when 750V battery packs are used).”

He added that the firm’s product ranges from €400-600 per kWh which is an “all-round carefree package without hidden costs” and that the average capacity over a 10-year lifetime will be at least 85%.

Energy-Storage.news then asked Truong what he saw as the main challenge for ESS companies in the coming years, to which he gave an interesting response.

“We do believe that just the matching of the batteries is not enough to ensure a long lifetime of the storage system. We think it is impossible to have such a precise matching of the batteries to avoid aging variations (because of different temperatures or marginal production variation) and therefore lose more capacity than needed,” he said.

“Second-life ESS companies will struggle with the deteriorating performance of their systems in the coming years (we heard that even 1st-life storage manufacturers have this problem with their older systems in the field).”

Truong then explained how Stabl’s proprietary technology would help it get around this: “Our inverter technology decouples the dependency of the battery modules and we can always access the full capacity of every battery module. In case a battery module needs to be swapped (because it is broken or lost too much capacity), this is a major deal for today’s architecture, where the storage system needs to be shut down for hours. STABL storage systems require a 10-minute break to easily swap the affected battery.”

It should be noted that other second life companies (such as California-based Element Energy) have also told Energy-Storage.news that their proprietary BMS also controls their BESS down to the module level. Another German second life firm, Voltfang, raised €5 million recently and said it “repurposes EV batteries at the module rather than pack level” although did not go as far as claiming that ability for its BMS’ control.

Some in the market have said that eventually, all commercial & industrial (C&I) use cases for energy storage could be served by second life BESS.

To this, Truong said: “We think a large share of the C&I segment could be served by second life. There will be applications that need high c-rates and we think that new high-power batteries are better suited for these applications.”

Energy-Storage.news looked at the second life market in depth for Vol.33 of PV Tech Power, Solar Media’s quarterly technical journal for the downstream solar and storage industry.

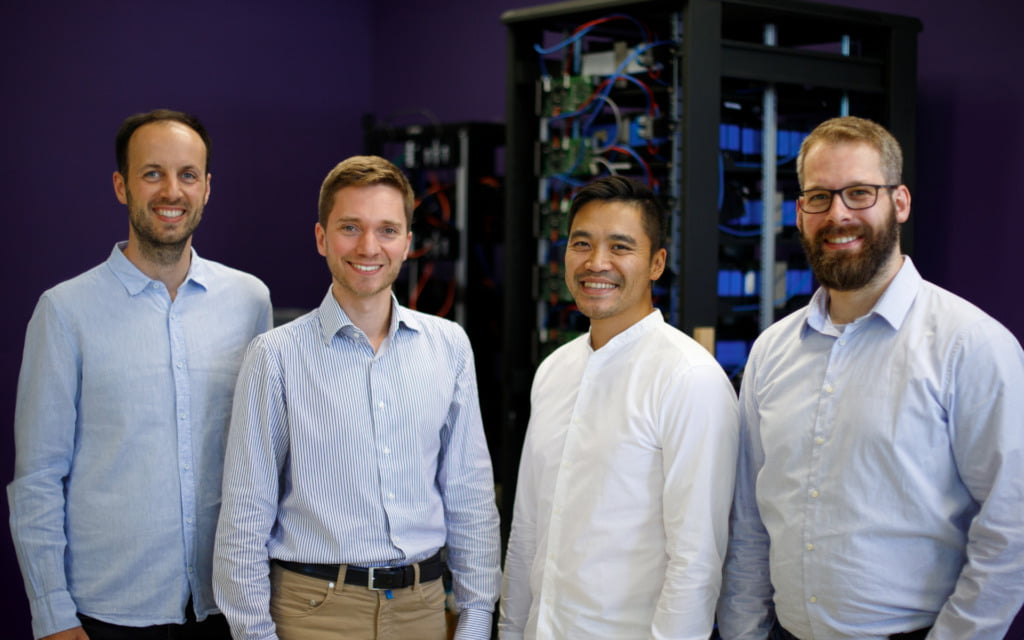

Dr Truong, second from left, with the rest of the Stabl team. Image: Stabl.

Continue reading