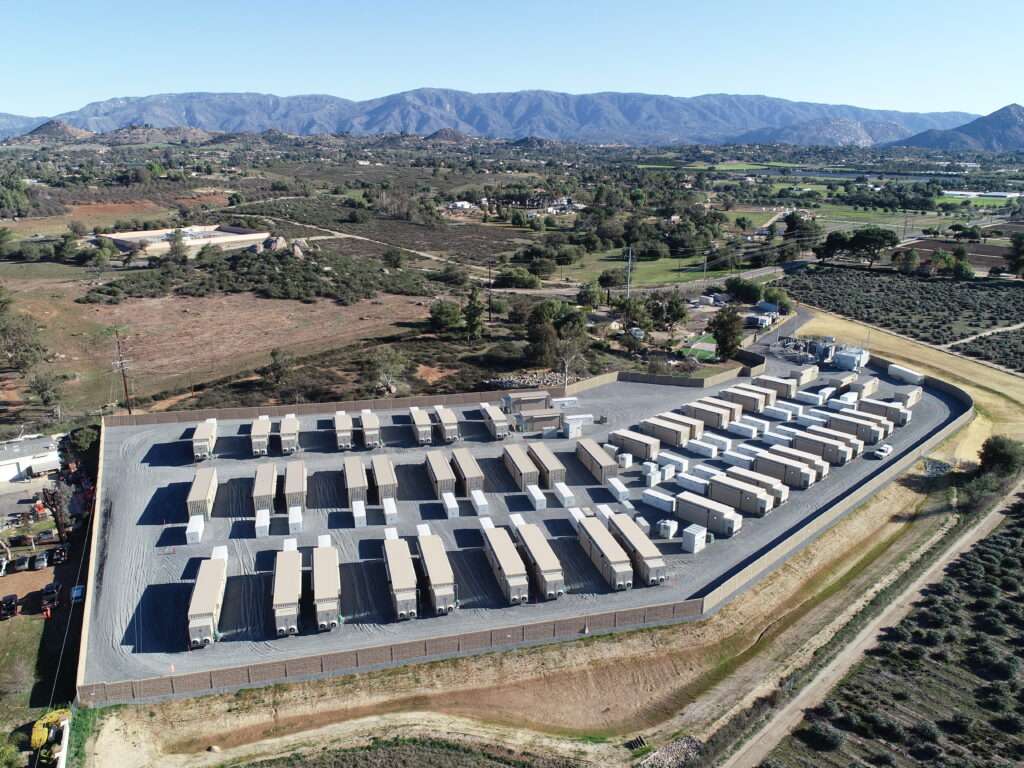

Rendering of a Rondo Energy system at an industrial site. Image: Rondo Energy.

A thermal energy storage project claimed to the be the first of its kind in the US, utilising the highest temperature thermal storage tech in the world to date, has gone online in California.

Technology provider Rondo Energy made its Rondo Heat Battery commercially available late last year, aimed at decarbonising industrial processes. Electricity fed into the devices is stored as heat in a brick-like material and then discharged as heat, electricity or a combination of both.

The company claims the ‘battery’ is more than 90% efficient, rising to as much as 98% for larger-scale systems, while it can operate at temperatures exceeding 1000°C and up to 1500°C. It is targeted at replacing furnaces and boilers used in sectors like steel, cement and chemicals, in which greenhouse gas (GHG) emissions are considered ‘hard-to-abate’.

Able to be fed with variable energy sources such as solar PV and wind, it can output that stored energy continuously over hours or days, offering a long-duration energy storage (LDES) solution using half as much electricity as would be required by today’s green hydrogen electrolysers, according to the manufacturer.

Rondo Energy has partnered with Calgren Renewable Fuels, a biofuels producer, and deployed its 2MWh system at Calgren’s production plant for ethanol, biodiesel, and renewable natural gas, in Pixley, California.

The Heat Battery has been installed on a commercial basis under a heat-as-a-service (HaaS) contract, meaning Calgren got it at no upfront capital cost, and at a cheaper cost of than an equivalent gas-fired heat-based solution. Rondo has claimed it as the first commercial deployment of a thermal storage solution in the US.

About half of emissions associated with biofuels production comes from the use of fossil fuel combustion in the refining processes, whereas the Rondo technology can be a drop-in replacement without changing Calgren’s existing production techniques and was done at Pixley without the facility experiencing any downtime.

“We’re looking forward to this unit proving itself, because we see the Rondo Heat Battery as a potential “perfect fit” solution for us—a low-cost source of zero-carbon heat for our facilities that can extend our reach toward the lowest-carbon, highest-value biofuels produced anywhere,” Calgren Renewable Fuels president Lyle Schlyer said.

Various companies are looking to commercialise different forms of thermal energy storage technology, many of them aiming at the commercial and industrial (C&I) sector, as Rondo is. They include US-based providers like Malta Inc, which has a proprietary ‘thermal hydro’ technology based on molten salt and Sweden’s Azelio, which stores energy at just under 600°C in a phase change material (PCM), to name just two.

At the recent Energy Storage Summit in London, Julia Souder, executive director of the global Long-Duration Energy Storage Council (LDES Council) trade association, highlighted that alongside power sector applications, heat is a huge piece of the addressable market for LDES technologies.

Rondo has put two models of its Heat Battery on the market, and noted that the system delivered for Calgren was made locally in California. The company’s backers include high-profile climate tech VCs Breakthrough Energy Ventures and Energy Impact Partners.

Energy-Storage.news’ publisher Solar Media will host the 5th Energy Storage Summit USA, 28-29 March 2023 in Austin, Texas. Featuring a packed programme of panels, presentations and fireside chats from industry leaders focusing on accelerating the market for energy storage across the country. For more information, go to the website.

Continue reading