Gigawatt-hours of used EV batteries are now hitting the market, and California-based Element Energy claims it has the ideal BMS platform to scale second life energy storage technology.

The firm recently raised a US$28 million Series B to accelerate the scale-up of its second life solution and proprietary battery management system (BMS) platform, as reported by Energy-Storage.news at the time. The firm is the latest in a series of companies repurposing used EV batteries into stationary energy storage systems (ESS) that Energy-Storage.news has interviewed.

Element also claims to have procured 2.5GWh of second life EV batteries, which is in the order of 10 times higher than its peers. CEO Anthony Stratakos wouldn’t give more detail on this when asked in a recent interview, preferring to discuss its BMS platform which he claims has numerous advantages over conventional technology.

The BMS platform is the core of the company’s value proposition, which wasn’t even focused on the second life space until recently, as he explains in this piece.

Stratakos also shared his thoughts on the trade-off of recycling batteries versus repurposing them into second life units and the future landscape of the second life energy storage market.

Energy-Storage.news: Tell us about how you came to found Element Energy?

Anthony Stratakos: At (high-density power solutions firm) Volterra we specialised in the miniaturisation of power conversion electronics which made it cost effective and power efficient to distribute power control down to the module level. In 2013, Volterra was acquired by Maxim Integrated (an analog and mixed-signal integrated circuits producer) where I served as CTO.

It became clear to us that optimising the performance of battery systems required more than a simple hardware solution – instead, a multi-faceted team with deep battery domain expertise was necessary to pull this off. Together with a few colleagues I spun Element Energy out of Maxim Integrated in 2019. At that point, we had spent 10 years developing and improving our proprietary BMS solution that featured architecture that deeply and granularly distributed the control of battery systems, and we began efforts to commercialise our products.

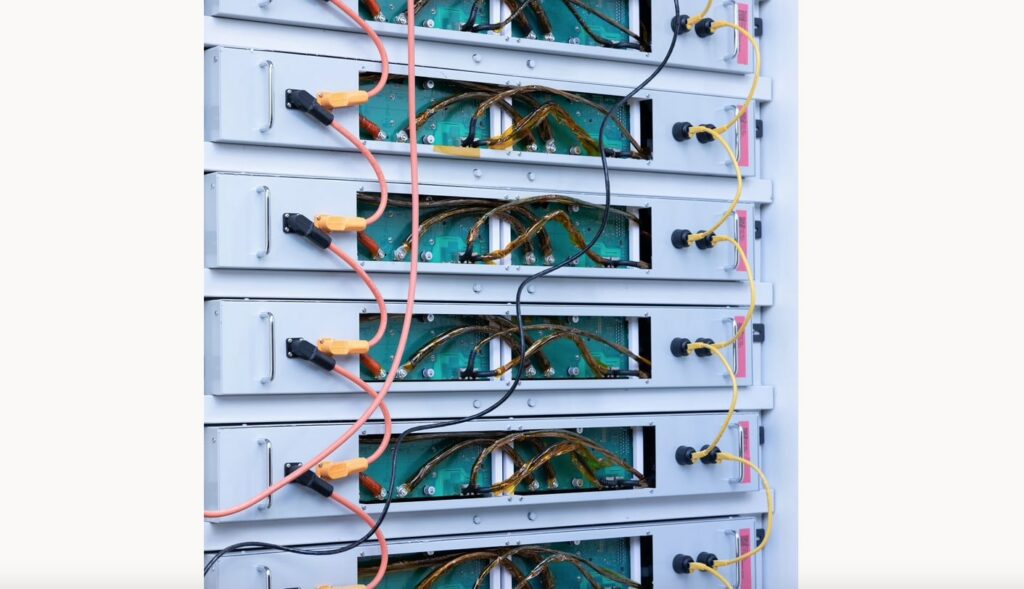

Today in our second-life applications for utility-scale battery energy storage we distribute power controls down to the module level.

What makes your BMS platform different to others and how is that applicable to second life solutions?

The power of our technology is that because our power control is distributed down to the module level, it works seamlessly with different battery technologies. This creates an opportunity to combine battery modules of different vintages, from different suppliers and at different states-of-health, capacities, and resistances.

Conventional BMS treats all the batteries the same, and charges and discharges them together as a single unit – as a result, any weak cell or module in the series string limits the energy storage capacity of the entire pack. And the fastest ageing cell limits the lifetime, performance, and overall energy harvest of the pack.

Our technology removes this constraint. With our Adaptive BMS, we generate more predictable performance out of a battery pack with greater throughput and a longer lifetime – further, we are able to run batteries down to a lower overall state-of-health while maintaining linear degradation. As a result, we create meaningfully better life-cycle performance and economics for battery systems.

The other key capability that our Adaptive BMS features that conventional BMS lack is the ability to run deep lab-grade diagnostics on batteries in the field on demand while they are operational. Conventional systems must be entirely taken off-line to run diagnostics, which is costly. Our in-the-field, real-time diagnostics creates enhanced predictive intelligence, safety, and reliability.

Through our diagnostics, we can actively analyse the physical mechanisms that contribute to differences in capacity fade; and we can detect unsafe potential failure modes, such as lithium plating, dendriting and certain targeted manufacturing defects – this predictive and real-time analysis is not possible with conventional technology.

And your move into the second life energy storage market?

Our vision has always been to be a broad-based BMS technology supplier to both ESS and EV applications, with full hardware, embedded software and cloud software.

But through the 50MW DOE-funded project we recently announced, we’ve moved into offering fully containerised battery energy storage systems. For that project we are the supplier of the containerised BESS while our partner is responsible for owning and operating the battery system.

We’re working with an industry-leading contract electronics manufacturer in the US to perform all the battery storage containerisation.

How quickly can you incorporate an EV battery module that you’ve never use before into your architecture?

Because of our deeply distributed architecture, our technology is widely compatible with batteries from different suppliers and comprised of different chemistries. Our power control electronics would remain the same but various algorithmic changes would be required. We expect to be able to incorporate battery modules from new suppliers within a few months of receipt.

What are your thoughts on the benefits of second life versus recycling?

I’m a firm believer that batteries should not be prematurely recycled – instead, their full life cycle energy should be harvested in every possible way first. Today, only a fraction of the battery materials can be effectively recycled, but recycling technologies are progressing rapidly. The economics and environmental benefits of reusing batteries are tremendous – we estimate that by 2030, by leveraging available second-life batteries the U.S. can reduce annual CO2 emissions by more than 10 million metric tons per year annually.

Further, the U.S. can avoid mining, processing and purchasing raw materials from unreliable foreign supply chains, which can save more than 11 million pounds of lithium and 20 million pounds of cobalt, along with the emissions and energy requirements of this value chain. On a global level, you can multiple the impact 5x.

And the future landscape of the second life market?

My view is that the second life battery opportunity is going to be so large and important from an environmental and circular economy perspective that automotive OEMs will develop the reverse logistics to collect used batteries from retired EVs and prepare them for redeployment to the power grid.

On a global basis, prior to the IRA passing, McKinsey estimated a 200GWh annual second life battery opportunity by 2030 – with the IRA passing and EV penetration rising, that number is expected to be far larger. By leveraging innovative technology, improved system architecture and data science, we can cost-effectively deploy EV batteries for another 20 years, create a high-impact, second-life battery economy and accelerate decarbonisation.

Energy-Storage.news’ publisher Solar Media will host the 5th Energy Storage Summit USA, 28-29 March 2023 in Austin, Texas. Featuring a packed programme of panels, presentations and fireside chats from industry leaders focusing on accelerating the market for energy storage across the country. For more information, go to the website.