FDRE tenders seek to guarantee the supply of renewable energy to entities connected to the Inter-State Transmission System (ISTS) across India, particularly at times of peak demand when solar PV may not be generating. As such, bids require an energy storage component to make the renewable power dispatchable.

In the case of the latest round, the fourth held by SECI to date, energy must be dispatched at an 80% Demand Fulfillment Ratio (DFR) in hourly blocks between peak hours from 1 April to 31 October. These are defined in SECI documents as 00:00 to 01:00, 14:30 to 16:30, and 21:00 to 24:00 each day during that period.

During the rest of the year, resources must deliver energy with a DFR of 90% on a monthly average basis.

Five bidders were awarded capacity, with tariffs of IR4.98/kWh (US$0.059/kWh) for the lowest three and IR4.99/kWh for the remaining two. They can be seen in the table below. Serentica Renewables bid with 250MW, but was awarded 100MW, as the above bidders already accounted for 530MW of the total 630MW up for award.

BidderQuoted tariff (IR)Loaded tariff (IR)Bid quantityVena Energy4.984.98100MWHero Solar Energy4.984.98100MWJSW Neo Energy4.984.98230MWHexa Climate Solutions4.994.99100MWSerentica Renewables 4.994.99250MW (100MW awarded)

Frameworks for the award of Firm Dispatchable Renewable Energy on a competitive tariff-based bidding model were published by the Union Government of India’s Ministry of Power in 2023.

While as of last month, a total of 10 tenders had been launched by various state agencies including SECI and power producer NTPC, totalling 12.1GW of renewable capacity, they have faced a few challenges along the way, in some cases requiring reconfigurations and amendments to make their terms less demanding for developers.

Expert Debmalya Sen, India lead for advanced energy solutions at the World Economic Forum (WEF) noted in a LinkedIn post that PPAs have been signed for 1.2GW to date, just over 8GW has been awarded or in the RFP stage, while 3.7GW has been cancelled.

For instance, from a 3GW NTPC tender and 1.5GW tendered by SECI in its second round of FDRE tenders, only 2.1GW was awarded, Sen noted.

For the newest FDRE IV procurement, SECI made some amendments between its launch in September 2023 and the reverse auction this week.

These included making the peak time DFR ratio less demanding, bringing it down from 90% to 80% and reducing the tendered amount from 1260MW to 630MW. The load profile was also changed from 15-minute to hourly blocks.

BRPL and BYPL will procure 625MW of dispatchable capacity and GIFT Plc 5MW.

The DFR will be furthered reduced for FDRE V, which Debmalya Sen commented may lead to a still lower price discovery for tariff bids.

Further information on SECI’s FDRE IV tender can be seen here.

Sterling & Wilson awarded 1,000MWh BESS EPC contract

Engineering, procurement and construction (EPC) firm Sterling & Wilson’s has been awarded a contract for 500MW/1,000MWh of standalone battery energy storage system (BESS) project work in India.

The India-headquartered firm’s renewable energy arm made the announcement today to the National Stock Exchange of India, noting that this would be the country’s largest BESS project to date, due to be executed by the end of 2025.

The firm said in the same announcement that it has also been awarded a contract to work on a 20MW floating solar PV project in the state of Karnataka. According to Sterling & Wilson, the total value of the two contracts is around IR3.28 billion (US$39.16 million).

The EPC contractor said both project orders came from the same client, but did not name it. However, according to a source Energy-Storage.news spoke to, it is very likely to be JSW Renew Energy Five, a subsidiary of JSW Energy, which is in the portfolio of Indian conglomerate JSW Group.

JSW Group won SECI’s first pilot tender for standalone battery storage, splitting the 1,000MWh capacity across two equally sized 250MW/500MWh projects, as reported by this site in January 2023. This is thought to be the project that Sterling & Wilson referred to. In addition to EPC work, Sterling & Wilson Renewable Energies will also carry out testing and commissioning of the systems.

India’s energy storage tenders, including FDRE, round-the-clock supply and standalone BESS tenders have been credited with kickstarting the country’s market and bringing down prices.

As of March this year, around 219MWh of BESS was online across the country, mostly paired with solar PV, but with India’s government targeting 500GW of new non-fossil fuel energy by 2030, including 450GW from solar PV and wind, the need for storage is acute, while beyond the 2030 timeframe, the national Central Electricity Authority (CEA) has modelled a need for 320GW/2,380GWh by 2047, about two-thirds from batteries in megawatt terms and the remainder from pumped hydro energy storage (PHES).

Jupiter Power puts Energy Vault BESS project into commercial operation in ERCOT

The company won the contract from BESS developer and operator Jupiter Power two years ago shortly before the companies announced an agreement to deploy 2.4GWh of BESS projects utilising locally manufactured technologies.

They claimed that, as for a project Energy Vault deployed for utility NV Power in Nevada earlier this year, the commissioning process for the St Gall project was a streamlined one. Earlier this year the firm won another 400MWh project from Jupiter Power.

The battery modules for the St Gall project were provided by Chinese battery OEM Rept, as shown in close-up picture (below) of the BESS containers from a video on Energy Vault’s website.

Energy Vault is primarily known for its gravity-based long-duration energy storage (LDES) technology but in the last two years has moved into deploying BESS as well as green hydrogen multi-day energy storage. CEO Rob Piconi told us in an interview last year that this was because the demand in the LDES space hadn’t taken off as fast as expected.

Image: Energy Vault corporate video.

The firm did however see its first large-scale commercial project using its gravity tech commissioned recently, in China, and has partnered with an architecture firm to explore deploying it in skyscrapers.

The company provided an update on its strategy in a recent investor and analyst day, outlining three key tenets for its strategic focus: addressing the world’s largest markets and growth regions, delivering more predictable and recurring revenues, and delivering strong growth and profitability.

It expanded into the Australian market earlier this year with a project order, but revealed that revenues in 2024 would be substantially lower than predicted.

The company is also expanding into asset ownership, initially through a project in California combining BESS and green hydrogen. It would not be the first LDES company to move from being a technology provider only to fully owning assets, with others including vanadium redox flow battery (VRFB) firm Invinity.

BESS arbitrage revenue in Australia’s NEM records 97% year-on-year increase amid volatility

This was more than enough to offset a major increase in energy costs of 155%, or AU$10 million, from the same period of 2023, AEMO said.

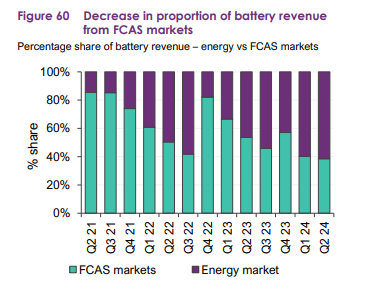

Indeed, energy trading continues to become a larger proportion of the revenue stack for battery storage systems than revenue secured through frequency control ancillary services (FCAS), a type of service controlled by the AEMO designed to secure the security of supply and prevent blackouts and power failures.

Total estimated net revenue for NEM grid-scale batteries this quarter was AUS$41.2 million, an increase of AUS$13.6 million from the AUS$27.7 net revenue earned in Q2 2023.

AEMO’s report revealed that FCAS revenue increased steadily YoY, with an increase of AUS$1.1 million, around 7%. However, this ultimately led to a YoY decrease in the proportion of overall revenue deriving from the FCAS market, with it down 39% in the quarter compared to Q1 and down from 54% in the previous year.

Image: AEMO.

As seen in the graph, Australia’s NEM, which covers the south and east of the country, has become an increasingly volatility-oriented market for BESS owners. Since Q2 2021, when energy market trading stood at less than 20%, it has grown to take up a much greater market share, around 60%.

Research conducted by Rystad Energy last year (October 2023) revealed that, amongst the 39 global electricity markets, NEM was identified as the “most volatile”, with the organisation stating that there was an urgent need for energy storage to mitigate this.

Drivers of the volatility being seen are primarily due to outages at coal power plants, the impacts of natural disasters on transmission infrastructure and the increasing penetration of variable renewable energy on the grid, mainly from solar PV. As such, Rystad concluded that by 2050, balancing the NEM will require 46GW/640GWh of energy storage.

It is worth noting that the volatility seen in the NEM is attracting international companies seeking to ply their trade in Australia. For example, as reported by Energy-Storage.news in 2022, Ireland-headquartered smart energy company GridBeyond entered the market, citing growing electricity supply volatility and the rising demand for distributed energy solutions in Australia as amongst their motivations.

New South Wales leads net revenue margins

From amongst the states connected to the NEM, including Victoria, Queensland, New South Wales (NSW), South Australia and Tasmania, NSW’s BESS assets captured the highest net revenue, around AUS$13.4 million – a 341% increase compared to Q2 2023’s AUS$3 million net revenue margin.

Of this figure, around AUS$11 million came from energy trading and AUS$2.4 million from FCAS markets.

The second-highest increase in net revenue figures came from Queensland, which saw a jump from AUS$4.7 million in Q2 2023 to AUS$10.3 million in this quarter. Most of this revenue, at AUS$6.7 million for the quarter, arose from contingency FCAS revenue.

There was also a YoY increase during the morning and evening peaks in this quarter. This increase is driven by the availability of additional batteries and higher spot prices. However, higher energy costs associated with charging offset the increased revenue earned when charging at negative prices (+AUS$0.5 million), resulting in a decrease in net revenue outside peak periods.

Image: AEMO.

Pumped hydro energy storage net revenue sees a vast increase

Alongside battery energy storage, pumped hydro energy storage (PHES) saw quarterly revenues rise by AUS$22.4 million year-on-year, representing a 76% increase.

The increase in spot prices corresponded to that rise, especially due to spot price fluctuations in NSW. Shoalhaven, a 240MW project, saw revenue from prices exceeding AUS$300/MWh, up AUS$14.9 million, around 468%, to reach AUS$18.1 million this quarter. Overall, Shoalhaven’s estimated net revenue was AUS$24.4 million, marking an AUS$17.1 million (235%) increase YoY.

Ormat signs California BESS agreement in shift from merchant to contracted revenues

The City of Riverside’s first RA contract requires Ormat to bring the project into operation by the guaranteed commercial operation date (COD) of 1 March 2026, although the company said it expects to be able to do so earlier, by the end of 2025.

Ormat develops, owns and operates geothermal energy projects, with additional business lines in waste-to-heat and energy storage technologies.

The energy storage division opened in 2020, following the company’s 2017 acquisition of energy storage developer Viridity. Ormat decided to enter the market to broaden its revenue base and noted in 2020 that the COVID-19 pandemic impacted revenues from its geothermal power generation and development as well as waste-to-heat generation.

To date, it has 190MW/318MWh of operational BESS assets in its portfolio, with projects in states including Texas, California, Ohio and New Jersey. In mid-2023, Ormat CEO Doron Blachar said the company was on-track to achieve a growth target that would bring its portfolio to 500MW-530MW and over 1GWh by the end of 2025.

Ormat CEO: ‘Segment transitioning to higher-growth’

At a 20 June 2024 Investor Day at the New York Stock Exchange (NYSE), where the company’s shares are listed, Ormat’s EVP of energy storage and business development Ofer Ben-Yosef said that the division has 335MW/1,040MWh of projects under construction which are scheduled to be online by the year-end 2025.

Energy storage comprised just 4% of the company’s total revenues in 2023, but Ormat sees it as a high-growth potential business, with Ben-Yosef pointing to market tailwinds such as the investment tax credit (ITC), the forecasted continuing growth of renewable energy deployments and equipment cost reductions.

Ormat also expected to see an ongoing shift in California and Texas from merchant opportunities to contracted revenues, noting that prior to 2023, California mostly saw 10-year RA deals with merchant upside, and the Texas market was pure merchant.

Post-2023, California will be characterised by up to 20-year tolling PPAs or RA contracts of between 10 and 20 years, with merchant upside, and Texas by tolling PPAs over 5-year to 7-year terms. RA and tolling agreement prices have risen by 20%-30%, Ben-Yosef said.

The company is also transitioning to executing larger projects, from average project sizes of 7.5MW/15MWh in 2018 as it entered the market, to 75MW/220MWh between 2024 and 2028.

While its other divisions are internationally diversified, Ormat Technologies’ energy storage division is focused on the US and has a claimed pipeline of 3.5GW/12.2GWh, of which California accounts for 2,105MW/8,420MWh of its development opportunities.

The company claimed 100% of its projects under construction as of Q1 2024 are eligible for the ITC. The Shirk project in Visalia for the City of Riverside is ‘currently expected to be eligible’ for a 40% tax credit, Ormat said in its announcement this week.

“The Shirk project shows the continued progress that Ormat has been making towards aligning our strategic growth focus to capitalise on key target markets in the US, such as California, while also transitioning our energy storage business to become a higher-growth segment with a balance of contracted revenues,” CEO Doron Blachar said.

California’s San Diego County votes to adopt BESS standards following recent battery fires

Fires at two of three approved BESS facilities in San Diego County

Jim Desmond’s concerns surrounding battery storage technology stem from recent high-profile fires at two of three BESS facilities green-lit for construction by San Diego County officials.

As reported in Energy-Storage.News, a battery unit at Terra-Gen’s 140MW/560MWh Valley Center BESS caught fire on 18 September 2023, causing a quarter-mile evacuation area that lasted until later in the evening, when the fire had been contained.

This incident was then followed by a much more significant fire at Rev Renewable’s Gateway Energy Storage facility that first ignited on 15 May 2024. An evacuation order was deployed by the California Department of Forestry and Fire Protection (CalFire) for San Diego that lasted until 28 May, while it worked to contain the fire.

In daily statements posted on X (formerly Twitter), CalFire reported several instances of thermal runaway at the Gateway site, deploying up to 40 fire personnel during the height of activity. The causes of both fires are currently unknown amidst ongoing investigations.

The third BESS facility approved by San Diego County officials is San Diego Gas & Electric’s (SDG&E’s) Fallbrook energy storage facility that was brought online in 2022. Ownership of the 40MW BESS was transferred from AES Corporation to the California public investor-owned utility (IOU) upon completion of the project under a build-own-transfer agreement.

Dozen active BESS applications in San Diego County

During the meeting, Desmond stated that there were currently 12 active BESS applications with San Diego’s Planning and Development Services department at various stages of the approval process, including another development from AES known as the Seguro energy storage project.

It was recently reported by local news outlet Coast News that the Palomar Health Administration had denied an easement which would have allowed the 320MW/1,280MWh BESS to connect to SDG&E’s Escondido substation via land owned by the Palomar Medical Center.

According to an AES website, the project was initially envisioned as having 400MW/1,600MWh of storage capacity but had been “reduced due to stakeholder and community feedback”.

San Diego BESS standards could incentivise use of industrial zones

During the meeting, Desmond explained that the development standards should stop developers locating BESS facilities in residential areas but also incentivise developers to locate facilities within industrial zones.

He also requested that at the next meeting, the board instate a temporary 45-day moratorium (with up to two 1-year extensions) on the approval of any new BESS facilities until the new standards had been adopted.

The development of BESS standards is expected to cost San Diego County up to US$1.25 million.

‘Really big problem’

The Vice Chair of the San Diego County Board of Supervisors Terra Lawson-Remer expressed concerns surrounding a potential two-year moratorium on the installation of new BESS facilities.

Lawson-Remer, also on the Board of Directors for California Community Choice Aggregator (CCA) energy supplier San Diego Community Power (SDCP), said that although she wanted to “move expeditiously” to create the new standards, it was her understanding that it could take up to two years or more for them to be developed, and that the county would have a “really big problem with local energy needs” if no new sites could be built during this period.

Instead of instating a blanket moratorium, the board passed a motion agreeing to adopt new standards but also decided that at the next meeting it would discuss several potential stopgap measures to incentivise BESS safety whilst the standards were being developed.

The board agreed that the discussion points should include a temporary moratorium on new BESS applications, mandatory board review of all new BESS projects and interim standards within six months.

Watch the 17 July 2024 Board of Supervisors meeting below, discussion of Item #8 on establishing development standards for siting of BESS begins at 1 hour 20 minutes.

[embedded content]

12-month moratorium for New York town

Elsewhere in the US, the Town of Wilson in Niagara County, New York recently enacted a 12-month moratorium on the processing of any new permits for projects with BESS facilities, whilst town officials drafted new local laws for battery siting.

At the Wednesday 17 July 2024 meeting, town supervisor Tony Evans said that the town would “take their time” drafting the new laws and would extend the moratorium if required.

Like California, there have been several high-profile fires at BESS facilities within the state of New York, including incidents at three separate facilities which occurred last year during May and July.

This led to the formation of the New York State Inter-Agency Fire Safety Working Group, which released its first set of recommended changes to the New York fire code during the first quarter of this year, as reported by Energy-Storage.News.

UAE utility EWEC seeking proposals for 400MW/800MWh BESS project

It follows its call for expressions of interest (EOI) in building the project earlier this year, which saw 27 parties qualified for the RFP out of a total 93 EOIs submitted. Parties have until the fourth quarter of 2024 to submit their response to the RFP.

The BESS will provide ancillary services, such as, frequency response and voltage control to help EWEC balance the grid as it increases its solar capacity to 7.5GW by 2030.

EWEC said the project will follow the model of the emirate’s existing Independent Power Producer (IPP) programme, where developers enter into a long-term agreement with EWEC as procurer.

Deploying the project will involve the development, financing, construction, operation, maintenance, and ownership of the BESS system and all associated infrastructure.

EWEC didn’t say when it expects the project to come online but has previously said the emirate needs 300MW/300MWh of energy storage online by 2026 to integrate its growing renewable generation portfolio, possibly giving an indication to the timeline for this project too.

Neighbouring emirate Dubai has been notably more quiet for large-scale BESS announcements in recent years. The last piece Energy-Storage.news published looking at it in 2021 covered a 8.61MWh system deployed by EWEC’s equivalent there Dubai Electricity and Water Authority (DEWA) using Tesla batteries. A large pumped hydro energy storage (PHES) is however underway, set to enter commercial operation this year.

TotalEnergies takes FID on 100MW/200MWh Germany project using Saft BESS

The oil and gas firm will invest €75 million (US$81.4 million) in the project which is expected to enter commercial operations in the second half of 2026.

Another TotalEnergies subsidiary, system integrator Saft, will provide its ‘iShift’ lithium iron phosphate (LFP) battery containers for the project, as Energy-Storage.news speculated it might when the transaction occurred in February. Saft has in the past deployed projects for TotalEnergies in the US, France and Belgium.

Another subsidiary, startup Quadra Energy, will provide optimisation services on the BESS project, operating its charging and discharging activity in the electricity market to maximise revenues.

France-headquartered TotalEnergies has been busy buying up companies across the renewable energy value chain in Germany, having also acquired Nash Renewables last year, a firm involved in optimising the design and operating parameters of renewable projects.

The 100MW/200MWh project in Dahlem is the joint-largest in Germany on which FID has been taken, with others including a system being built by developer MW Storage and system integrator Fluence.

The sector has picked up in Germany in the last few years as high ancillary service prices and wholesale arbitrage have substantially improved the business case, leading even companies from tangential segments to enter the space.

That includes commercial & industrial (C&I) focused provider Tesvolt launching its largest ever project recently and vehicle-to-grid (V2G) software specialist The Mobility House announcing it would go into the grid-scale segment.

The ‘Innovation Tender’ subsidy scheme for solar-plus-storage projects, which pays out an operating grant per kWh discharged, is also helping drive deployments with 512MW of co-located projects awarded contracts in the last round.

US IPP BrightNight gets grid connection approval for Australia hybrid solar project

“Australia’s increasing energy demand, alongside that of the broader region, presents vast opportunities for us to provide our cutting-edge renewable energy solutions to drive the adoption of clean energy,” said Jerome Ortiz, BrightNight APAC CEO.

Projects such as these will help Victoria meet its renewable power generation targets, which include the goal of renewable power accounting for 40% of the state’s electricity generation share by 2025. Victoria is well on track to meet this target – the share of renewable power in the state’s energy mix has increased from 12.2% in 2013-14 to 37.8% in 2022-23 – and currently has over 1GW of utility-scale solar capacity in operation, with more than 5.3GW of capacity approved and a further 190MW of capacity currently under construction.

The Mortlake project will also help meet the state’s energy storage goals, with the government aiming to install 6.3GW of energy storage capacity by 2035. Planning documents submitted by BrightNight to the Victorian government note that the Mortlake project will meet up to 11% of the state’s 2030 storage capacity target, and up to 5% of the state’s 2035 storage capacity target.

To read the full version of this story, visit PV Tech.

Australia: Origin Energy’s 2GWh BESS expansion plan for Eraring coal power site approved

This will complement Origin’s existing 460MW/1073MWh 2-hour duration BESS currently under construction as part of Stage 1 of the overall project.

Stage 1 of the Eraring project is expected to cost around AU$600 million (US$392 million) and be delivered by Wärtsilä, a Finnish marine and energy technology company, via an engineering equipment delivery (EED) contract with Origin. It is expected to come online at the end of 2025.

Origin has already signed equipment supply and construction agreements for Stage 2 of the project. Wärtsilä has again been employed to deliver the battery equipment, with Enerven Energy Infrastructure providing design and construction services. Construction will begin in early 2025 and be completed in Q1 of 2027.

Wärtsilä revealed that the BESS will operate in virtual synchronous machine (VISMA) mode. This will enable short-circuit current capabilities, such as reactive current, droop control, and synthetic inertia, to support grid stability and security. This will be achieved via Wärtsilä’s energy management system, GEMS Digital Energy Platform.

According to Greg Jarvis, head of energy and supply at Origin Energy, the project affirms the company’s belief that “storage will play an important role in the changing grid by helping to firm up variable supply from wind and solar”.

“The second stage of the Eraring battery will be over 4-hours duration and it will be capable of absorbing excess solar generation during the day to support reliable energy supply when needed, such as through the evening peak,” he added.

Project significant in withdrawing Australia’s biggest coal-fired power plant

Readers of Energy-Storage.news may be aware that the Eraring battery energy storage project is part of Origin’s plans to withdraw Australia’s largest coal-fired power station from service and instead contribute to the uptake of variable renewable energy generation technologies, such as wind and solar.

Located on the shores of Lake Macquarie, southwest of Newcastle, the black coal power plant provides 2,880MW to the National Electricity Market (NEM). In early 2022, Origin said it would be retiring the coal-fired power plant in 2025, yet in May 2024, the New South Wales government controversially extended this by an additional two years to “guarantee a maximum of electricity supply”. The new expected closure date is scheduled for August 2027.

This was in light of the Australian Energy Market Operator (AEMO) stating that, without Eraring, New South Wales would face energy reliability risks from 2025. As such, the state government is subsidising the power station to ensure it can remain operational.

Although the decision remains controversial, global market research organisation Cornwall Insight revealed that extending Eraring’s service will cut New South Wales’ power prices by 44%, dropping from a predicted AU$153/MWh to AU$86/MWh in 2026. However, question marks remain over the power station’s use and impact on New South Wales and Australia’s climate goals.

Roadblocks in delivering infrastructure to transition from coal

The extension of the Eraring coal-fired power station could have been avoided had infrastructure been scaled sufficiently in the state, yet despite an appetite to scale this from a developer perspective, “roadblocks” remain, Stephanie Bashir, CEO of energy policy and regulation specialist Nexa Advisory, said at Solar Media’s Energy Storage Summit Australia in Sydney earlier this year.

“These types of roadblocks are fairly and squarely in the hands of government to expedite and then make sure that we’re not just building to the timeline to close power stations (which we’re failing miserably as a result) but also to have a bit more ambition to be the energy superpower we actually can be.”

The good news is that Australia has the policy mechanisms in place and the technologies available to achieve that more ambitious goal.

“We just need to get on with it,” Bashir said.

Equis secures grid approval for 200MW BESS

In other Australian news, Equis Australia, the regional subsidiary for Asia-Pacific market infrastructure developer Equis, has secured grid approval for its 200MW/800MWh Lower Wonga BESS in Queensland.

Based around 0.8km southwest of the Woolooga Substation, around 100km northwest of Sunshine Coast, the 4-hour duration BESS was granted development approval in July 2023.

According to the project’s website, construction will commence in 2024 and be operational in 2026. Once construction begins, the BESS project will create up to 115 regional jobs.

Earlier this year, Equis Australia, alongside the State Electricity Commission (SEC) for Victoria, secured AU$400 million in financing for their Melbourne Renewable Energy Hub (MREH) battery storage project. The project will comprise three BESS assets with a total output of 600MW and a capacity of 1.6GWh.

Utility offtake agreement signed for gigawatt-hour scale BESS project in Arizona

The 4-hour duration lithium-ion (Li-ion) battery asset will be constructed in Mesa’s Elliot Road Technology Corridor, an industrial development hosting high-tech manufacturing and tech companies.

Tenants include Apple, Meta, Amazon, and others. Google is also due to set up some operations at the development. The city of Mesa has provided utilities infrastructure, speedy permitting processes, and a Foreign Trade Zone, with Salt River Project providing power to the industrial park.

Aypa Power, formerly known as NRSTOR C&I before its acquisition by private equity giant Blackstone in 2020, took over the project from another developer, Eolian. The pair jointly bid Signal Butte into SRP’s 2023 all-source request for proposals (RFP).

Aypa Power, which bought the project during late-stage development from Eolian, will continue to own it, while utility SRP has full rights to control the dispatch of stored energy into its grid.

It marks Aypa’s first BESS project in Arizona. The company’s other major announced projects are in the US battery storage hotspot states of California and Texas, with two further projects in Indiana, one of which was purchased also from Eolian.

The project is due to go into commercial operation by mid-2026. Eolian CEO Aaron Zubaty commented last week that its location in Signal Butte was chosen strategically in 2018 due to the presence of a substation serving “multiple operating and under-construction data centres”.

“The continued growth of our economy now depends more than ever on deploying fast-responding and flexible resources in the right locations to provide critical instantaneous capacity, and battery energy storage projects like Signal Butte can be built at a speed that matches and enables continued rapid growth in electricity demand,” Zubaty said.

Arizona utilities adding BESS resources through RFPs

Meanwhile, SRP and the desert Southwest state’s other main electricity supplier, Arizona Public Service (APS), have signed a number of similar agreements for large-scale battery storage projects in recent months.

Earlier this month a tolling agreement between APS and developer Strata Clean Energy was announced for a 150MW/600MWh standalone BESS project, and in June SRP held a celebration event to officially ‘open’ two projects from Plus Power, adding a combined 340MW/1,360MWh of battery resources to the utility’s portfolio.

These projects have all earned their utility contracts through participation in utility RFPs. SRP is currently hosting its 2024 peak power all-source RFP (PDF), launched in April. Through it, the company wants to add 200MW of peak generation capacity by May 2026, and at least another 300MW the start of May 2027, as well as 500MW of new carbon-free energy resources.

In addition, SRP recently launched an RFP specifically for the procurement of long-duration energy storage (LDES) resources from non-lithium storage technologies for deployment in the early 2030s.