Revenues were down substantially quarter-on-quarter, however, nearly 90% lower than the US$6.6 million in Q1.

Overall, it ended up with a net loss of US$28.2 million in Q2, much lower than the US$131.6 million loss in Q2 2023.

The firm manufactures a proprietary zinc-based battery pack which it sells to system integrators for projects with up to 12 hours of discharge duration.

Highlights during the quarter included a US$315 million financing package with private equity firm Cerberus and the expansion of a microgrid project with the Viejas Band of Kumeyaay Indians in California to 60MWh from 35MWh previously.

The company repeated what it said in its Q1 results, that it expected the ramp-up in manufacturing to help its profitability shift this year.

It claims a commercial pipeline of US$13.8 billion and an orders backlog of US$586.8 million, although these figures have been questioned by influential short-sellers in the past.

Energy Vault

Energy Vault meanwhile provides gravity energy storage technology as well as battery energy storage systems (BESS).

It saw a 90% drop in annual sales in Q2, to US$3.8 million, which it said reflected seasonality and timing of project revenues. Its cost of goods sold however also came down, by 92.5% to US$2.7 million, meaning its adjusted EBITDA loss narrowed from US$18 million to US$15.8 million.

It reiterated full-year guidance for 2024 of US$50-100 million, a substantial decrease from 2023.

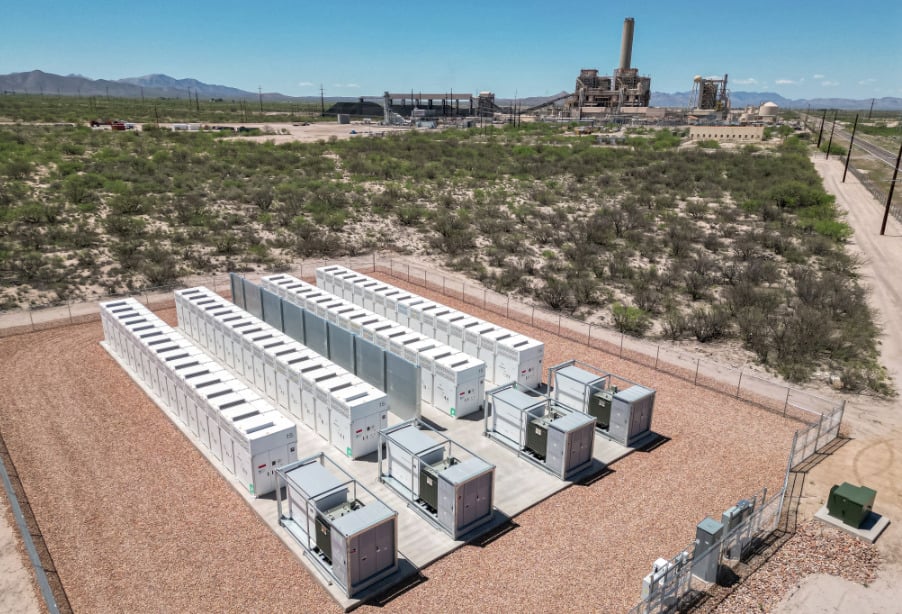

BESS projects commissioned in and around the quarter include projects in Nevada and Texas while it has also made several recent announcements about its gravity storage tech, including new form factors one of which it is exploring deploying at a coal mine in Italy. The technology however has its fair share of critics, to put it mildly.

Both Eos and Energy Vault were part of an article Energy-Storage.news published last year looking at how energy storage SPAC-listed firms have fared since going public (Premium access).

Mixed Q3 for Fluence: revenue and guidance down but orders and profits up

Fluence said the revenue fall was down to the ‘timing of product deliveries’, the same reason it gave for a revenue fall in its Q2 (January-March). The same happened with numerous other system integrators, and most sources have said this is largely down to delays in getting BESS projects online in the US due to supply chain and grid infrastructure completion issues.

The trend appears to have affected its full-year performance too, with the company narrowing down – though not reduce the bottom end of – its revenue guidance. It is revising its full-year forecast to US$2.7-2.8 billion from US$2.7-3.3 billion previously, and its adjusted EBITDA to US$55-65 million from US$50-80 million previously.

However, the company’s profit margins improved in the quarter, with its GAAP gross profit margin more than quadrupling to 17.2%, a net income of US$1.1 million versus a US$35 million loss the previous year and adjusted EBITDA of US$15.6 million versus negative US$27.5 million a year prior. It also saw its quarterly order intake more than double year-on-year to US$1.3 billion leaving it with a backlog of US$4.5 billion, a record.

Fluence is one of the world’s largest BESS providers globally by projects deployed and contracted and also has a strong digital offering, which will have brought its annual recurring revenues (ARR) to US$100 million by the end of the financial year.

The firm also revealed recently that it will provide 2.2GWh of BESS to asset owner Excelsior for US projects that will qualify for domestic content investment tax credit (ITC) incentives under the Inflation Reduction Act (IRA).

In its Q3 presentation, it explained that using using cells and modules that are manufactured in the US will enable it to ‘easily’ meet the domestic content thresholds required for BESS. The threshold starts at 40% for 2025, and US-made cells comprise 38% and modules (packaging) comprises 3.3%, pushing it over the line. A thermal management system is 4.9%, battery management system (BMS) 5.2% and production of the overall battery pack is another 21%.

It said it expects deliveries of US-made cells from supplier AESC to start in December 2024, ramping up over the course of 2025. It’s not clear if that is the same supplier for the Excelsior deal, which it didn’t name but said would be from a factory in Tennessee, while AESC’s announced gigafactory is in neighbouring Kentucky.

Akaysha begins construction of 410MWh BESS in Queensland, Australia

Akaysha has confirmed that the Brendale BESS will incorporate Tesla Megapack technology, with Consolidated Power Projects Australia Pty Ltd (CPP) set to deliver the Balance of Plant (BoP).

Tesla Megapack has been used across several Australian sites, including RWE’s 50MW/400MWh Limondale BESS in New South Wales.

Akaysha is also using Megapacks at its 1,660MWh Orana BESS, located in the Central-West Orana Renewable Energy Zone (REZ), in New South Wales.

However, the developer has a multi-supplier approach and for its biggest project to date, the Waratah Super Battery project, also in New South Wales (slightly larger than Orana at 850MW/1,680MWh), system integrator and manufacturer Powin is providing the BESS solution.

Akaysha, backed by major global asset manager Blackrock, closed project financing for the Orana BESS in July. The AU$650 million three-year agreement will fund the construction of the BESS in the Central-West Orana REZ. It includes AU$75 million in support for project security obligations with a Letter of Credit.

The Brendale BESS project aims to provide energy arbitrage and Frequency Control Ancillary Services (FCAS) to support the national electricity market (NEM) and facilitate the integration of solar PV and wind projects by utilising the existing transmission infrastructure in the region.

Paul Curnow, managing director and chief commercial officer (CCO) at Akaysha Energy, said the Brendale BESS is a “crucial step” in the company’s mission to deploy large-scale BESS.

“The Brendale BESS is an important element of Akaysha Energy’s portfolio across not only Queensland but the NEM more broadly. It is a crucial step in our mission to rapidly deploy large-scale BESS, enhancing grid stability and energy security while driving the global shift to sustainable energy,” Curnow said.

“The Brendale BESS is one of four projects under development in the state and it’s clear that the Queensland energy sector is serious about the transition. Once operational, the Brendale BESS will significantly bolster the delivery of a stable supply of energy to the local community.”

Shell Energy signs UK’s first single-asset BESS tolling agreement for 330MWh project

In 2021, global energy storage owner-operator BW ESS and Penso Power, which deploys, owns and manages grid-scale battery energy storage projects, announced a joint venture that will see BW ESS fund the build out of Penso’s UK project pipeline totalling over 3GWh.

The fixed price tolling agreement will provide revenue certainty for BW ESS and Penso Power while Shell trades the Bramley BESS into a range of ancillary services and wholesale markets. Shell will pay the owners a fixed fee for the BESS and keep all the upside.

It may be the first tolling deal of this size for a single asset, but the first major UK tolling deal announced in the UK was by Gresham House and Octopus Energy for a 568MW portfolio of operational projects earlier this year. Gresham House New Energy assistant fund manager, James Bustin, recently spoke to Energy-Storage.news Premium about that deal, suggesting that it “woke up the wider market to the possibility” that tolls could be an option for their projects.

The 100MW/330MWh Bramley site is also the first project in Europe to deploy Sungrow’s PowerTitan 2.0 liquid cooled BESS – a system that combines a 2.5MW Power Conversion System using integrated string inverters and a 5MWh battery into a single container.

“This tolling agreement, which has been some time in the making, demonstrates the attractiveness of longer-duration, higher-performance battery systems,” BW ESS CEO Erik Strømsø said.

“It not only secures long-term revenues for Bramley, but also helps enable the market’s shift away from short-term frequency response towards load shifting.”

According to Rupen Tanna, head of power and systematic trading at Shell Energy Europe, because tolls are a feature of conventional energy trading, Shell has “the trading experience to add significant value, while supporting the UK’s ongoing energy transition”.

This story first appeared on Solar Power Portal.

Philippines: Renewable energy policies and rural electrification drive battery storage push

We brought you a write-up of the panel, ‘Growing the Japanese storage market,’ just over a week ago. Now, it’s the turn of ‘Building BESS in the Philippines,’ which brought up just as many interesting talking points about a very different but equally important market.

The afternoon panel followed the keynote address by Philippines Department of Energy (DOE) Assistant Secretary Mario C. Marasigan. During his speech in the morning, Marasigan announced that the next round of the government Green Energy Auction Program (GEAP) would be for renewable energy systems with integrated energy storage.

More details emerged on that round, GEA-4, last week. Alongside, Marasigan, representatives of leading private sector names in the Philippines renewables, storage and power industry gave their thoughts on renewables integration with storage, off-grid electrification and much more.

Speakers:

Hon. Mario C. Marasigan, Assistant Secretary, Philippine DOE

Jason Soberano, VP and chief business development officer, SNAP (SN Aboitiz)

Joanna Mae Millares, project execution manager, Aboitiz Power

Colin Steley, VP for storage and board of trustees

Dr Ruth Briones, chairman and CEO, Greenergy Solutions

Moderator:

Eric San Pedro, business development, Entoria Energy

Policy questions DOE is handling

Moderator Eric San Pedro at renewable energy developer, investor and asset owner Entoria Energy kicked off by asking DOE Assistant Secretary Marasigan about the policies and incentives in place to support the integration of battery energy storage system (BESS) technology in the power sector, and specifically with renewables.

The government sees energy storage as a vital enabler for the Philippines’ “ambitious targets” for renewable energy, Marasigan said, aiming for 35% renewables in the energy mix by 2030, 50% by 2040 and continuing to rise from there.

“We have to integrate everything that we can make use of to ensure that those targets will be met,” he said, including, of course, energy storage, but specifically BESS as the most suitable mature technology for near-term deployment.

As has been seen in markets across the world, and the governments and regulators that oversee them, the Philippines has questions to answer on the classification of storage systems for the grid.

“We have to classify whether these energy storage systems will be considered as generators, we have to classify them as well whether these are providers of ancillary services, and lastly, what if we integrate these energy storage systems with renewable energy that serves as a component [of that renewable energy asset] rather than a separate one?”

In the last instance, incentives available to renewable energy generators would also be accorded to energy storage, Marasigan said, with every kilowatt-hour produced by renewables and stored in batteries considered renewables by regulators.

Upcoming Green Energy Auction for integrated renewables and storage

The Assistant Secretary noted that for the upcoming GEA-4 renewables-plus-storage solicitation, winning projects would maintain the must-run or priority dispatch status that renewables.

The auction will aim to accelerate the development of the Philippines’ renewable energy resources and get projects commissioned on time and align power sector investments with policy targets

Moderator Eric San Pedro said that the first two GEA tenders for variable renewable energy (VRE) had encountered some issues, primarily, he said, because low prices bid “were somewhat difficult to achieve”.

Marasigan acknowledged these challenges for developers in arriving at the right bid price. DOE is working with the Energy Regulatory Commission (ERC) to come up with different pricing mechanisms for energy storage systems.

Dr Ruth Briones of Greenergy Solutions, a Philippines-headquartered developer of renewable energy specialised in utility-scale projects, said that Greenergy successfully bid for GEA-1 and GEA-2 project that are going ahead to commissioning and commercial operation.

For GEA-4, however, the DOE and industry need to figure out a more complex set of financial equations, Briones said, as well as conquer some unique technical challenges and understand policy frameworks that themselves are a work in progress.

Energy storage is a technology that can not only drive the modernisation of power infrastructure in the Philippines, but also attractor investors in the country’s economy.

“However, as a utility developer, we are looking at challenges in the implementation of the policy framework, and at technology challenges,” Briones said.

For example, permitting complexities as well as environmental factors such as scarcity of land mean that Greenergy is tending to go work on smaller utility-scale solar-plus-storage projects rather than larger ones in the Philippines.

“How do we respond to this? There will be a lot of feasibility studies to be done, especially to help the system operator respond to the issues, and also, the permitting process is not easy if you have co-located projects. Permitting in solar PV alone is challenging and even more if we’re going to co-locate the BESS project,” Briones said.

At the same time, it is difficult to attract investors to finance solar-plus-storage projects with uncertainties over the business case. The optimal price per kilowatt-hour, the Internal Rate of Return (IRR), how to sell the stored energy are all questions that need to be answered.

At this stage in the market, feasibility studies are “trial and error,” the Greenergy CEO said.

Big power players leveraging existing generation sites

The Philippines’ power generation sector is dominated by a handful of big power producers, backed by the country’s major industrial conglomerates.

These have largely taken the lead in deploying grid-scale BESS, including Aboitiz Power, subsidiary of holding company Aboitiz Equity Ventures. As part of a rollout of 248MW of BESS, Aboitiz Power (AP) has completed a 49MW project on a floating power barge on Mindanao Island.

AP project execution manager Joanne Mae Millares said that the floating BESS, paired with an existing 100MW diesel plant to reduce its ramping time from 15 minutes to just three, is a “very unique innovation” and, as such, faced some of those challenges Briones referred to.

There were no “firmed up regulations for BESS at that time,” Mae Millares said, and AP had to help come up with a protocol for the “hybrid diesel generator (DG)-BESS,” and in terms of permitting essentially followed whatever the local government asked the company to do, “in order to finish the project if not on time, then as early as possible”.

What is also notable is that projects by power companies like Aboitiz Power or San Miguel Power Corporation (SMPC) are being installed, like the Mindanao barge, at existing power plant facilities. As regular readers of Energy-Storage.news might be aware, battery storage can greatly increase the efficiency of power plants, behind which lies the business case and what one expert described as a race between power companies to add those BESS enhancements.

In addition, AP already has existing land available for BESS additions at its thermal plants.

“We will continue to do that, to integrate BESS with our thermal plants, and at the same time, we will be starting to integrate BESS with our renewable portfolio,” Mae Millares said.

At the moment, AP’s BESS assets perform frequency regulation ancillary services, because its thermal plants have contracts in place to do so in the Philippines’ highly regulated electricity market. However, in addition to capacity-based ancillary service markets, BESS could also participate in reserve markets, which are energy plays.

By contrast, SN Aboitiz Power Group (SNAP), which is a joint venture (JV) between Aboitiz Power and Norwegian state-owned renewables developer Scatec, made its first BESS project a standalone one that provides ancillary services through participation in the reserve market.

SNAP’s Magat BESS is co-located with, but operates separately from, an existing hydroelectric plant of the same name. Image: SN Aboitiz Power.

The project, which operates separately but is co-located with an existing hydroelectric plant, went into operation in January. SNAP intends to ramp up its 24MW/36MWh output and capacity to 240MW and is currently running a tender.

However, as SNAP VP Jason Soberano noted, the reserve market has been closed since February.

This was to allow for adjustments to the Wholesale Electricity Spot Market (WESM) design, to align the reserve market’s 1-hour dispatch interval with 5-minute intervals for trading in the energy market.

While it had been expected to reopen in late July, shortly after Energy Storage Summit Asia took place, this did not happen. A few days ago (2 August), the DOE said it targeted the resumption of the market “early this month”.

Despite this, Soberano said SNAP was “excited for incentives and how the market would move,” looking forward to seeing how batteries could be integrated with renewables in behind-the-meter (BTM) projects, and regulations being drafted by the DOE and ERC.

“We can’t just pump in more renewable energy and not take care of the grid itself,” Soberano said.

Off-grid: renewables, BESS with diesel backup

As Eric San Pedro pointed out, it’s also important to remember that the Philippines is an archipelago with more than 7,000 islands.

The moderator asked Assistant Secretary Marasigan about specific policies and frameworks for battery storage as part of off-grid systems in many of the outlying island regions.

The DOE is preparing to launch its second competitive solicitation for implementing microgrid systems in rural areas, he said, targeting deployments in around 48 different locations the department has identified.

Those microgrid systems will comprise renewable energy, energy storage, and backup facilities, typically diesel generators.

Marasigan noted that the first round, held last year, “was not that successful,” with projects awarded to private sector bidders in just eight identified locations out of 41, but said lessons have been learned from that experience.

“We have identified the challenges of the developers, and we hope that by addressing those challenges, there will be more participants,” Marasigan said.

In addition to that procurement, there will be programmes to incentivise the retrofit of renewables and storage at existing off-grid diesel microgrids, hosted via the National Power Corporation coordinating with the country’s Small Power Utilities Group (SPUG).

Longer durations ‘would be beneficial’

An audience member asked if the panel envisaged the Philippines BESS market moving toward 2-hour or even 4-hour duration systems.

“Definitely,” said DOE Assistant Secretary Marasigan.

“We are hoping that the improvement and enhancement of energy storage systems, particularly the batteries, will be one of the drivers for us to attain our targets in renewable energy,” he said.

Philippines President Ferdinand Marcos Jr cutting the ribbon to inaugurate a large-scale BESS facility. Image: ABB.

The DOE is looking to use every tool in its disposal to ensure that “every kilowatt-hour generated” is useful for the nation’s consumers, and that includes transition fuels too. The DOE has said that alongside integrated renewables and storage, it is considering liquid natural gas (LNG) procurements through the GEA-4 mechanism.

It is a matter of practicality, Marasigan said.

The renewable targets “will be met by looking at all possible solutions,” and batteries are in the front running of that assessment right now.

“What we have readily at hand would be the batteries, because even if we consider that pumped storage hydro will be one of those better solutions, it will take us at least seven years before we can come up with the pumped storage hydros in realisation.”

That said, the DOE’s ongoing GEA-3 auction is open to pumped hydro, and other non-battery-based storage technologies.

SNAP is developing PHES plants as well as BESS and Jason Soberano said that the mechanical storage technology may be more viable for long-duration energy storage (LDES) projects of 8-hour duration than lithium-ion (Li-ion) batteries.

Even so, 4-hour duration Li-ion plants would be beneficial, Soberano argued, helping to provide mid-merit power generation—filling some of the gap between peaking power and baseload—until longer duration storage can help renewables replace the thermal generation baseload too.

The Energy Storage Summit Asia, hosted by our publisher Solar Media, returns to Singapore in July 2025. Energy-Storage.news Premium subscribers can benefit from exclusive discounts on tickets to this and other events in the Summit series.

Funding for US grid upgrades includes US$147 million for 8.5GWh ‘multi-day’ battery storage

As reported by our colleagues at PV Tech earlier today, the DOE selected eight projects in total spanning 18 US states for a share of US$2.2 billion funding for transmission infrastructure and technology upgrades.

The awards form part of the Grid Resilience and Innovation Partnerships (GRIP) Program, which in total will pay out more than US$10 billion, and was created through the Biden-Harris Administration’s Bipartisan Infrastructure Law.

In total, close to 13GW of new grid capacity will be opened up by the projects, enabling the addition of renewable energy including 4.8GW of offshore wind, and hardening the grid’s resiliency from outages while increasing overall reliability. The expected load growth coming from data centres and manufacturing is a big driver of those needs.

Within that remit, innovative new technologies are also being supported.

Iron oxide battery startup Form Energy announced that its technology will be used as part of the Power Up New England project. A statement from the company’s CEO Matteo Jaramillo revealed that an 85MW Form Energy system with 100-hour duration (8,500MWh), will be deployed at the former paper mill site in Maine.

That means that, while relatively small in megawatt terms (power output), the multi-day project’s duration and therefore capacity makes it the largest single battery storage project announced to date in megawatt-hours.

The world’s largest standalone lithium-ion (Li-ion) battery energy storage system (BESS) project in operation today is the 3,000MWh Moss Landing Energy Storage Facility in California, while Edwards Sanborn Solar and Storage Project, also in California, and as the name suggests, a hybrid solar-plus-storage project, has 3,278MWh of BESS onsite.

Those are the operational projects, but even the world’s biggest announced in development so far, including one in the Philippines and another in Australia, range in planned capacities between about 4GWh and 5GWh.

Funds form part of total US$389 million Power Up New England award

Back in April, a statement on behalf of the New England states about Power Up New England was published by the Connecticut Department of Energy and Environmental Protection, revealing that the project had applied for the GRIP programme Federal grant funding.

It also stated that the project was backed by a consortium of private sector organisations including energy storage developer Elevate Renewables, utilities Eversource and National Grid, and an unnamed “multi-day energy storage technology provider”.

Energy-Storage.news had taken that to be Form Energy which a source later privately confirmed ahead of this week’s announcement.

The office of Massachusetts governor Maura Healey said yesterday that Power Up New England had been awarded a total US$389 million funding via GRIP, of which US$147 million was earmarked for the Form Energy system.

Form Energy has been developing and commercialising a novel battery technology based on oxidisation i.e., rusting, and deoxidisation of iron as the battery charges and discharges.

It revealed the battery chemistry after coming out of stealth mode in 2020, and claimed it is suitable for very long-duration energy storage (LDES) applications with around 100 hours the sweet spot. The materials used are also abundant and cheap, and able to be sourced domestically within the US, Form Energy has said.

The multi-day energy storage provider is building its first factory in West Virginia and has scored a number of pilot project agreements with utilities around the US.

“Located at the site of a former paper mill in rural Maine, this iron-air battery system will have the most energy capacity of any battery system announced yet in the world,” Matteo Jaramillo said yesterday.

“The project will ensure a more reliable, clean, and affordable grid in New England by reducing transmission congestion and making valuable wind energy resources available when and where they are needed. By locating the project at an EPA brownfield site, we look forward to driving local job growth and other community benefits.”

Stem Inc slashes FY guidance, launches strategic review after plummeting sales and bookings

Projects completed in the quarter include three solar-plus-storage arrays in Arizona for utility AEPCO.

Its margins improved, bar an 18% increase in its EBITDA loss to US$11.3 million. However, a one-time non-cash US$547 million impairment of goodwill led to a net loss of US$582 million.

Goodwill is typically generated when a company is acquired or publicly lists on the stock market, and represents the difference between its value post-deal and its tangible assets. As Energy-Storage.news has reported, the company’s share price has fallen substantially since listing via the SPAC route (as have other SPAC firms), so the goodwill impairment may reflect a re-evaluation in light of that.

The company’s bookings also fell substantially, down almost 90% to US$25.4 million (verus US$236.4 million) in the same quarter last year. The firm said this was ‘driven primarily by increased quarterly variability associated with Stem’s continued expansion into large, utility-scale projects’. However, its contracted backlog increase by 14% from the end of 2023.

The company has subsequently revised down full-year guidance. It is now forecasting US$200-270 million in revenue, less than half the previous US$567-667 million estimate, while bookings will be US$600-1,100 million versus US$1,500-2,000 million previously guided for. It has dropped its guidance of positive adjusted EBITDA too.

The company has initiated a strategic review of the business and appointed a new CFO in Doran Hole, who was previously CFO and executive VP at renewable energy, energy efficiency and storage project company Ameresco.

The firm is trading at US$0.56 at the time of writing, down over 40% from around US$1.00 before the results release.

Ambri, Nilar, AMTE: A look at recent bankruptcy events in the ESS battery space

Ambri: investors pulling out in ‘challenging fundraising environment’

US-based liquid metal battery firm Ambri’s Chapter 11 bankruptcy and recent sale of assets to a consortium of its lenders was covered by Energy-Storage.news last week. The firm’s technology is based around liquid calcium anodes and molten salt electrolyte.

Filing for Chapter 11 bankruptcy protection is different to a Chapter 7 one, which immediately kickstarts the process of asset sales, and Ambri has now come out of the process with a new CEO.

A statement by company CFO Nora Murphy in a filing from June 2024 with the bankruptcy court of Delaware court explained how the company ended up financial difficulties.

The company had been doing well in demonstrating its product development until 2022, raising nearly US$150 million in equity. In June that year, it entered into a lease for a Milford, Massachusetts space to set up a high-volume production facility for its battery technology. However, it required a ‘significant and costly buildout’, Murphy said, with US$18 million invested between June 2022 and 5 June 2024, when it filed a petition for Chapter 11 bankruptcy.

Ambri launched a Series F financing round in Spring 2023, which it would use to build out the Milford facility as well as fund R&D and working capital.

However: “Like many pre-revenue companies in the renewable energy space, that initialgrowth was interrupted by an incredibly challenging fundraising environment,” Murphy said, referring to the increase in interest rates globally.

“Although Ambri had initially secured an anchor investor for the round, this anchor investor declined to participate towards the end of the process. In turn, Ambri sought a replacement anchor investor. investors, due to softness in the market, Ambri was unable to secure a replacement anchor investorfor the Proposed Series F Financing and could not complete the Series F financing round thatwould have enabled it to meet its cell development milestones and manufacturing initiatives.”

The company then went to existing investors for a U$50 million of bridge financing, which was initially agreed only for one to then also pull out, leaving an US$8 million shortfall. Though the company attempted to reduce its burn rate, including by laying off 105 employees in November 2023, it could not secure enough concessions from its creditors to relieve liquidity constraints.

Ambri, an MIT spin-out, said the recent sale of assets would be the best avenue to recapitalise the company and secure its future. The company may have a more unique value proposition than other budding ESS battery technology firms, with its focus on the data centre market.

Read the Delaware filing in full here.

Nilar: slowdown in Swedish market and high commodity prices

In November 2023, Sweden-based nickel metal hydride battery company Nilar International AB filed for bankruptcy with a district court after it failed to find a solution to ‘strained and urgent liquidity needs in both the short and long term’.

Losses for Nilar International AB ran to 600 million SEK (US$57 million) in 2021 and 287 million SEK in 2022 according to Swedish company registry site Allo Bolag.

Last month, zinc-ion battery technology company Enerpoly acquired Nilar’s end-to-end battery production line and process development capabilities, as part of its efforts to set up a zinc-ion gigafactory this year.

Nilar had been trying to develop and manufacture batteries for the stationary energy storage system (ESS) market, and said its technology had higher safety and recyclability than other chemistries. Its facility and head offices were both located in Gävle.

In 2020, it received a €50 million (US$55 million) loan from the European Investment Bank (EIB) to commercialise and scale up and then IPOed on the Sweden Nasdaq a year later.

In an earnings call a month prior to the bankruptcy application, discussing the ESS market which it was targeting, Nilar CEO Erik Oldmark alluded to potential problems the company was facing.

“Even though are expecting tremendous growth in the market, for the time being we are seeing a bit of a slowdown in the Swedish market, driven by a few things. Firstly, we have lower electricity prices compared to the last two years, due to a very wet summer,” Oldmark said.

The latter point presumably refers to the impact that has on Sweden’s hydropower production, one of its main sources of electricity.

“Combined with the decrease in the Swedish currency and higher interest rates, that has put a pause on deployments in the Swedish market. But, it’s not something we see in the European market which has a completely different logic in its energy market which puts demand on ESS in a favourable place.”

Enerpoly meanwhile said, when announcing the acquisition, that Nilar’s battery chemistry used expensive raw materials and thus suffered from high commodity prices.

AMTE: delays in onboarding new investor

Also in November 2023, Scotland-based sodium-ion battery tech firm AMTE Power Plc said that it no longer had sufficient funds to continue operating and had appointed administrators FRP Advisory to seek potential buyers of the business and assets of the company. A year prior it had said its sodium-ion cells were ‘nearly ready’ to send to customers.

The decision was taken after private equity backer Pinnacle declined to advance funds under a convertible loan facility. AMTE had been developing products for electric vehicles (EV), ESS and ‘other speciality markets’.

In February 2024, three months later, FRP announced that it had secured the sale of part of the trading business and assets of AMTE to LionVolt, a Dutch battery technology startup.

AMTE made a £3.8 million (US$5 million) pre-tax loss in the year to 30 June 2021, at which point it identified a ‘significant funding gap’ and two of its five products development was ‘significantly delayed arising from difficulties in scaling up’, the administrators said according to Insolvency Insider UK. That scuppered plans for a Dundee gigafactory, and the loss grew to £6 million in the year to June 2022.

FRP was initially appointed to handle an accelerated mergers and acquisitions (AMA) process – used for distressed assets – in mid-2023 but no viable offers were received, shortly before Saudi-based Pinnacle came in with one. However, due diligence delays meant the money did not come in time. A second AMA led to the £3.05 million offer from LionVolt which was accepted.

The administrators’ report didn’t go into detail on why AMTE ultimately did not survive, but gave a few clues. It said that, although the company was the first sodium-ion manufacturer in Europe to certify a cell, it suffered delays in developing its products due to financial pressures. The uncertainty led to a fall in headcount from 70 in July 2023 to 35 at the time of the administration, all but one of which were voluntary departures, FRP said.

The company board also said that the 2022 Autumn statement by chancellor Jeremy Hunt—the UK’s chief finance minister—negatively contributed to AMTE’s future because of its negative impact on the markets. 2023 also saw a second attempt to certify a new cell product fail.

Proterra and Azelio

Other companies in the energy storage space to have entered bankruptcy proceedings in the past year include US battery pack manufacturer Proterra, which was sold to Volvo, and thermal energy storage technology firm Azelio, based in Sweden.

Canadian Solar supplying BESS for FRV Australia’s first standalone storage project

The project secured connection agreements with AusNet in 2024 and, according to FRV Australia, is situated in a “strategic location on the electricity grid”.

During the development of the Terang BESS, FRV Australia expects that the project will generate up to 150 jobs during the construction phase and hire three to four permanent operational staff. Additionally, FRV Australia said it will provide site maintenance contracts to local businesses.

Carlo Frigerio, CEO of FRV Australia, said that getting the company’s first large-scale standalone BESS to financial close represents a “major achievement” for FRV Australia.

“This project shows our commitment to different renewable energy technologies and strengthens our place in the renewable energy sector. It paves the way for future innovations and growth in our portfolio,” Frigerio said.

FRV Australia closes refinancing deal to aid expansion

The project, which will be aided by the financial close of an AUS$1.2 billion (US$780 million) refinancing facility announced last week (31 July), will provide additional stability to the national electricity market (NEM) as further variable renewable energy generation technologies are added.

According to FRV, the refinancing ensures robust financial support for the construction of the Terang BESS and other future projects, enhancing FRV Australia’s ability to continue operating in the Australian renewable energy sector.

Eleven financial institutions participated in the refinancing process, including ING Bank, Westpac Banking Corporation, MUFG Bank, Société Générale, Norddeutsche Landesbank, Mizuho Bank, Intesa Sanpaolo, United Overseas Bank, the Clean Energy Finance Corporation, China Construction Bank, and the Agricultural Bank of China.

FRV Australia, a subsidiary of Jameel Energy and the Canadian infrastructure fund OMERS, announced that the funding will currently support all solar PV plants in its portfolio and lay the groundwork for further expansion in the Australian market.

It is worth noting that, at the beginning of July 2024, FRV Australia turned its first solar-plus-storage project online: the Dalby, Queensland project. The site comprises a 2.45MWdc solar PV plant and a co-located 2.54MW/5MWh BESS.

The project’s engineering, procurement and construction (EPC) work was carried out by Spanish company Gransolar.

Ausgrid launches energy storage-as-a-service offering as community BESS goes online in NSW, Australia

The offering also grants additional benefits for Australians, such as improving grid reliability and supply security, and could also help facilitate the greater integration of renewable energy.

Ausgrid’s new Bondi community battery, a 160kW/412kWh system, becomes the organisation’s ninth asset, and the sixth to be launched under the Federal government’s Community Batteries for Household Solar Program. The Bondi system is also connected to an electric vehicle (EV) charger, allowing drivers to charge up with renewably sourced electricity.

Australia’s minister for climate change and energy, Chris Bowen, believes the ESaaS plan is the next step in the “evolution of the community batteries” and could relieve cost-of-living pressures.

“It’s incredibly exciting to deliver a community battery for Bondi today, our Reliable Renewables plan is bringing cleaner, cheaper reliable renewable energy to communities across the country,” Bowen said.

Indeed, the coupling of solar PV technology with these community batteries could support residential decarbonisation and create an additional incentive to introduce renewable energy generation technology to homes, even if the building has no access to a home BESS asset. This is where the community BESS’ strengths come to the fore.

Ausgrid has already installed community batteries to support households in Beacon Hill, Bankstown, Cameron Park, Cabarita, Narara, Warriewood, North Epping and Bexley North. Each community BESS a designated catchment area and is set by Ausgrid based on network connectivity and battery benefit.

EnergyAustralia’s managing director, Mark Collette, believes the service could play an important role in the energy transition.

“EnergyAustralia is focused on making energy simple for customers, combining customer assets into our portfolio to deliver the most predictable and affordable outcomes. Community batteries help the wider community coordinate their energy assets improving reliability, affordability and sustainability outcomes for everyone,” Collette said.

Community batteries in Australia continue to grow in number, and this is set to increase further. The Australian Renewable Energy Agency (ARENA) recently allocating AU$143 million in financial backing to build 370 community assets across Australia.

Indeed, the organisation’s Community Battery Funding Round 1 initiative will allocate funding to 20 applicants across all of Australia’s states and territories. ARENA anticipates the initiative will unlock around AU$359 million of investment in renewable energy infrastructure.

Queensland and New South Wales will receive the most community batteries, with 69 and 95, respectively, followed by Victoria with 37 batteries, Western Australia with 28, South Australia with 24, the Northern Territory with 16, and Tasmania with six.

ARENA stated that the batteries will benefit various energy consumers, such as households, hospitals, schools, and other facilities.

Readers of Energy-Storage.news will also be aware that the City of Melbourne recently switched on its first community BESS last month at Council House, as part of its ‘Power Melbourne’ scheme.

The newly installed battery system has an output and capacity of 450kW/1.1MWh, and the council aims to have 5MW of similar assets. Another BESS is expected to be installed at Boyd Community Hub in July, with another one planned for the Library at the Dock later this year.

Market consultancy group Sunwiz also weighed in on the potential of community BESS in Australia, which it dubbed the “Year of the Big Battery”. The group said adding that community battery—or ‘neighbourhood battery’ projects around Australia, classified within the commercial and industrial (C&I) segment—will help drive a 50% growth in C&I installs in 2024.