It recorded an EBITDA loss of US$18.8 million and revenues of just US$348,000 for the second quarter of 2024, ending the quarter as of 30 June with US$74.4 million in cash and equivalents.

ESS Inc. CEO Eric Dresselhuys said that delays by a key partner had resulted in lower-than-expected revenues, which are expected to “resolve in the coming weeks,” while the company’s plan to move into “volume manufacturing and shipments remains solidly on track”.

Share prices were at US$0.56 per share yesterday after ESS Inc. listed them on the New York Stock Exchange (NYSE) at US$10.00 in December 2020.

They hit a brief high of US$18.75 in November before falling. ESS Inc. received a listing notice from the Securities and Exchange Commission (SEC) in March, and on 8 August, the company filed a definitive proxy statement with the SEC to execute a reverse split, which, once effected following a special shareholder meeting next week would put the flow battery company back into compliance.

ESS Inc. CFO: EXIM loan ‘should support cash needs well into 2025’

Despite these challenges, in presentations and an earnings call with leadership, the company emphasised the demand it expects to see both in the US and internationally for long-duration energy storage (LDES) technologies of the type it produces.

It also highlighted various project and technology development milestones, including a 25% increase in energy density resulting from improved electrolyte chemistry, cutting the commissioning time for its Energy Warehouse product in half and a near-60% reduction in costs for the Energy Warehouse’s production.

ESS Inc. also put emphasis on the fact that its batteries and storage systems can be produced domestically in the US, which is why it has been able to enter negotiations with the Export-Import Bank of the United States (EXIM) for up to US$50 million in funding.

The EXIM deal, disbursed under the state institution’s Make in America Initiative, is a “transformative agreement,” CFO Tony Rabb said.

While it is still in negotiation with EXIM, ESS Inc. expects to draw down US$10 million from that low-interest loan this year, helping the company to “fully fund” current and future capacity expansion.

“We’re extremely well positioned to continue to expand our production capacity through this EXIM financing facility, effectively funding all of our production capacity CapEx needs through 2025 and into 2026,” Rabb said.

“This transformative agreement bolsters our liquidity levels, and we expect should support our business cash needs well into 2025.”

Dresselhuys noted that the plan going into 2024 had been to “moderate” product builds and shipments during the first half of the year, before scaling in the second half once cost reduction had been implemented.

Rabb added that another 40% reduction in the cost of Energy Warehouse production—ESS Inc.’s commercial and industrial (C&I) product—is expected to be achieved during 2024.

Recently published research from the US Department of Energy’s Office of Electricity found that flow batteries are among the LDES technologies, defined as providing 10-hours or more storage duration, with the greatest cost reduction potential through 2030.

Meanwhile, the first unit delivered of the utility-scale Energy Center flow battery system is already cycling at the site of Oregon utility Portland General Electric (PGE), and a second unit is being built for delivery to the customer.

ESS Inc. hopes to make ‘live announcements’ from Honeywell partnership in coming months

Other recent highlights included the start of commercial operation of ESS Inc.’s first overseas project, at Schiphol Airport in the Netherlands, thought to be the first flow battery deployed at an airport.

There was also the award of a US$10 million California Energy Commission (CEC) grant for an ongoing collaboration with California utility Sacramento Municipal Utility District (SMUD) and the selection of ESS Inc. flow battery tech for another CEC-supported project for a microgrid with Native American-owned developer and system integrator Indian Energy. Another California project for community energy supplier Burbank Water & Power was inaugurated in June, with 75kW output and 500kWh capacity.

Meanwhile, the initial engineering contract has been completed for another overseas project for the German utility LEAG. That project, at which the lignite-burning European utility is procuring a 50MW/500MWh (10-hour) flow battery system as part of an energy transition strategy to deploy 2-3GWh of LDES, has a targeted COD in 2026 and is now moving into the detailed engineering phase.

In response to a question from analyst Davis Sunderland, equity research associate at Baird around progress on a partnership with US automation technology provider Honeywell, CEO Dresselhuys said that Honeywell CEO Vimal Kapur had recently visited ESS Inc.’s premises in Wilsonville, Oregon.

“Honeywell certainly has a great appreciation, as we do, for the market environment and the mandate to get down the cost curve as fast as possible. So we’re at the stage now where the go-to-market teams have been organised,” Dresselhuys said.

“We’re putting proposals out to people and our hope would be that we’ll be able to translate that into live announcements with people here over the coming months.”

Dresselhuys spoke with Energy-Storage.news Premium at last year’s RE+ trade event in the US, discussing the potential for LDES technologies, the iron flow battery’s perceived advantages over lithium-ion and other flow battery technologies, as well as offering insights into specific projects and deals.

Conference call transcript by Seeking Alpha.

PNNL opens US DOE energy storage research facility, long-duration LCOS analysis published

Grid Storage Launchpad (GSL) will test, validate, and accelerate new battery materials for stationary energy storage and transport applications in configurations of up to 100kW in 35 laboratories designed to resemble realistic conditions. PNNL said in an announcement last week (13 August) that GSL will be ‘uniquely equipped’ for this type of work.

Construction began in April 2022, as reported by Energy-Storage.news, and its cost was cited at US$75 million at the time.

The bulk of the funding came from the DOE’s Office of Electricity in collaboration with the Office of Science. The Clean Energy Fund (CEF) of Washington State contributed US$8.3 million.

DOE funding was committed through the FY 2021 Energy and Water Development Funding Bill, approved by the US House Committee on Appropriations in summer 2020. GSL’s work to accelerate energy storage development was considered a “national priority”, alongside US$500 million support for energy storage manufacturing and US$770.5 million in grants to US-based manufacturers of advanced batteries and components.

PNNL director Steve Ashby said the new R&D centre will “house some of the world’s most accomplished scientists and engineers from PNNL, other national labs, academia, and industry—working together to develop real-world solutions that will benefit our nation and the world”.

Flow batteries, pumped hydro among technologies that could unlock ‘promise of long-duration storage’

GSL’s opening comes a couple of weeks after the Office of Electricity (OE) published a report, ‘Achieving the promise of low-cost long-duration energy storage’, which the office said charted a path towards understanding the investments and time required in that endeavour.

Part of the DOE’s Energy Earthshots programme to advance R&D and commercialisation of sustainability technologies, the report is a synthesis and amplification of a 2023 technology strategy assessment for achieving a US$0.05/kWh cost of long-duration energy storage (LDES).

“This report is one example of OE’s pioneering R&D work to advance the next generation of energy storage technologies to prepare our nation’s grid for future demands,” OE assistant secretary Gene Rodriguez wrote in the report’s foreword.

Defined as technologies capable of storing and discharging energy over 10+ hours, the DOE has targeted a cost reduction in LDES of 90% from 2021 to 2030, recognising current high prices as a major barrier to widespread deployment.

The full report (PDF) describes 10 different technologies across electrochemical (e.g. flow batteries, sodium-ion, lithium-ion, zinc, supercapacitors), chemical (hydrogen), mechanical (pumped hydro and compressed air) and thermal energy storage categories.

The OE found that flow batteries and the two mechanical storage technologies could achieve the Earthshot’s US$0.05/kWh levelised cost of storage (LCOS) goal by the end of the decade.

Meanwhile, lithium-ion (Li-ion), lead-acid and zinc batteries will have an LCOS of less than US$0.10/kWh as the target date approaches, sodium-ion (Na-ion), lead-acid and zinc batteries could hold the greatest cost reduction potential (falling by US$0.31/kWh to 2030) and pumped hydro energy storage (PHES), supercapacitors (supercaps) and flow batteries will see the next biggest LCOS drops of about US$0.11/kWh.

That said, results vary greatly and the OE said additional analysis and research may be useful given the relative lack of industry data available.

For example, the average investment required to facilitate achievable cost reductions of 12% to 85% across the top 10% of innovation portfolios ranged from US$86 million to US$1,063 million and could take between five and 11-and-a-half years, the report said.

In a separate project to GSL, Pacific Northwest National Laboratory is installing a vanadium redox flow battery (VRFB) system from Anglo-American manufacturer Invinity Energy Systems with a 24-hour discharge duration. As reported by Energy-Storage.news in November 2023, the 525kW/12,600kWh VRFB is being installed at PNNL’s Richland Campus in Washington State.

Iron-air ‘multi-day’ energy storage startup Form Energy breaks ground on first pilot project

The two companies said last week (15 August) that groundbreaking has taken place on the Cambridge Energy Storage Project, set to go into operation in late 2025.

Great River Energy, a non-profit cooperative, will evaluate the iron-air battery system’s operation over ‘several years’—the exact length of the assessment was not specified in last week’s announcement.

While it has since been joined by a number of other pilot deployments announced by Form Energy, the Minnesota project was the first the tech company revealed back in mid-2020 as it emerged from stealth mode and before it even disclosed the battery chemistry a few months later.

‘Renewables as baseload’

The company’s CEO, Matteo Jaramillo, spoke with Energy-Storage.news for interviews as Form emerged from stealth mode, claiming that the battery could complement the roles of lithium-ion (Li-ion) and other technologies like flow batteries and pumped hydro, enabling renewable energy to serve as ‘baseload’ for the grid.

This is due not only to its capability of providing several days’ worth of storage, but also the abundant materials used in its production, which Form claim enable low cost of production.

The project with Great River Energy will be a 1.5MW system with 100-hour duration (1500MWh). That’s somewhat revised from the originally announced sizing, of 1MW to 150-hour duration, albeit with the same megawatt-hour capacity.

Other projects in the works for the iron-air battery include a system of 8.5MW/8,500MWh, to be built in Maine, US, supported by federal Department of Energy funding and announced earlier this month.

That project will receive a share of DOE funding for reinforcing and upgrading transmission networks across the US. It is part of Power Up New England, a transmission project across the states that comprise the region, aimed at increasing the New England ISO’s capacity for integrating renewables, with 4.5GW of new wind energy earmarked for deployment.

Others in the works from Form Energy include pilots with utilities Xcel Energy, also in Minnesota, Georgia Power in the southern state of the same name and Puget Sound Energy in Washington, as well as Pacific Gas & Electric (PG&E) in California.

The startup is currently building its first factory in West Virginia, where the company said the iron-air system for the Great River Energy pilot will be manufactured soon. Minnesota-headquartered construction group Mortenson has been appointed for engineering, procurement and construction (EPC) duties.

“We hope this pilot project will help us lead the way towards multi-day storage and potential expansion in the future,” Great River Energy general manager Cole Funseth said.

Acen Australia secures IPC approval for 1.2GWh solar-plus-storage project in New South Wales

The system will also provide grid stability services and backup capacity to ensure the security of supply.

This approval also marks the first generation and storage project approved for connection to the Central-West Orana Renewable Energy Zone (REZ) transmission network. The REZ recently transitioned into the delivery phase, as reported by PV Tech last month.

According to planning documents, the project will feature around 1.2 to 1.4 million solar PV modules alongside associated mounting infrastructure up to 4.7m in height. An on-site substation with a connection voltage of up to 500kV will also be created.

Construction is anticipated to begin in late 2026 – early 2027 for six months, and it will have an expected operational lifespan of 30 years. However, the project may include infrastructure upgrades that could prolong its longevity.

It is worth noting that the Birriwa solar-plus-storage project will be located next to two other solar projects developed by Acen Australia. These are the 400MW Stubbo solar PV project, at which construction began in November 2022, and the 320MW Narragamba solar project. These projects will connect to new transmission infrastructure developed by the Energy Corporation of NSW (EnergyCo) as part of the Central-West Orana REZ.

With secured approval, Acen Australia said it will turn its attention to preparing for construction, including developing temporary workers’ accommodation, implementing its strategy to employ local staff where possible, and sourcing goods and services from local businesses.

Acen Australia submitted assessment documents for the Birriwa solar-plus-storage through the Federal government’s Environment Protection and Biodiversity Conservation Act (EPBC), last week (12 August).

Construction starts of New England Solar BESS switchyard

Acen Australia also confirmed yesterday (18 August) that construction of a 200MW/400MWh BESS at the site of its proposed 720MW New England Solar project in New South Wales, is one step closer, with work set to commence expanding the Uralla site’s Transgrid switchyard.

The project consists of two stages. The first 400MW stage, comprising about one million solar modules, has been generating clean electricity since 2023. A second stage will then add an additional 320MW of generation capacity alongside the BESS.

Acen Australia project director Sarah Donnan said: “These initial infrastructure works, to expand the switchyard, are an exciting step in the delivery of what is set to be the first large-scale BESS in New England.”

Ormat signs seven-year tolls for two ERCOT BESS projects

Both projects are expected to come online in Q4 2025 and are the first for which Ormat has secured tolling deals in the ERCOT market. The firm said the deals allowed it to proceed with the construction of a third project, the 100MW/200MWh Louisa project.

Tolls are a type of deal where a company, in this case Equilibrium, pays an asset owner, in this case Ormat, a fixed fee to rent and trade the BESS in the energy market.

Doron Blachar, CEO of of Ormat Technologies, said: “By securing fixed, long-term revenues, we have de-risked approximately 50% of our strategically expanded Texas storage portfolio, aligning with our long-term plan to improve segment profitability and accelerate our growth.”

The firm also recently signed a resource adequacy (RA) agreement for a BESS in California, which is akin to a toll in that it is a long-term, guaranteed source of revenues. Such long-term agreements are less common in ERCOT, however.

Tolls are growing in popularity in the energy storage market, long-used in US and Australia but beginning to emerge in the UK too, with recent deals from asset owners BW ESS and Gresham House.

Sodium-ion push accelerates as China and US announce gigawatt-hour production facilities

California-headquartered Natron Energy will build a sodium-ion gigafactory facility in Edgecombe County, North Carolina, with an eventual production capacity of 24GWh, it said yesterday (15 August).

The company didn’t give any firm timelines for commercial operation or ramp-up of the facility, only saying it is a 12-year project. The US$1.4 billion investment will be its second major production facility after a the launch of commercial operations earlier this year at a 600MWh factory in Michigan.

Its capacity will primarily go to the ESS market, with Natron saying it will meet demand for “critical power, industrial and grid energy storage solutions”.

The North Carolina facility is supported by a Job Development Investment Grant (JDIG), approved by the state’s Economic Investment Committee earlier today, and the project will also apply for a US$30 million grant from the North Carolina Megasite Readiness Program.

Furthermore, Natron Energy should be able to benefit from 45x tax credits for US domestic battery production under the Inflation Reduction Act (IRA), which pay out US$35 per kWh of battery cell capacity produced and another US$10 per kWh of modules. The firm said its product is the only UL-certified sodium-ion battery in the market today.

Proponents say that sodium-ion technology promises low cost, long lifespan, high safety, and high energy density although critics say it still faces many challenges in scaling up cost-effectively.

China: sodium-ion plans much further ahead

China, meanwhile, is much further ahead in its push towards production of the battery technology, with much nearer-term projects progressed by two companies recently.

Zhejiang Hu Na Energy recently officially registered and coded its operational annual production of 4GWh of sodium-ion battery cells and modules, along with 1.5GWh of lithium-ion battery modules, at its facility in Nanhu, Jiaxing, Zhejiang Province.

The overall facility is planned to reach 20GWh of sodium-ion production capacity, the company said when launching the project in November last year. The investment in the first 4GWh phase totalled CNY1.125 billion (US$157 million), around three quarters of which was accounted for by equipment costs.

A bulletin detailing the first phase ramp-up was published as a bulletin on the District Natural Resources Planning Bureau website.

In concurrent news, a company called Harbin Bona New Energy is to start building a 2GWh sodium-ion battery production facility at the end of this month, according to Shanghai Metals Market (SMM). The project is in the city of Harbin, Heilongjiang Province.

The facility will produce square sodium-ion cells as well as related energy storage system integration.

California city green lights Arevon’s 800MWh BESS, finds ‘less than significant’ impact on surroundings

Potential for ‘significant effect’ on the surrounding environment

Projects requiring discretionary approvals from government agencies, such as land amendments and use permits, which have the potential to cause an impact on the surrounding environment are subject to the CEQA review process.

The lead agency will first prepare an Initial Study (IS) to determine whether the new project could have a “significant effect” on the environment, defined by CEQA Section 15382 as “a substantial, or potentially substantial, adverse change in any of the physical conditions within the area affected by the project including land, air, water, minerals, flora, fauna, ambient noise, and objects of historic or aesthetic significance.”

If the lead agency decides the project won’t have a significant effect on the environment, it will publish a Notice of Determination (ND) approving construction of the project.

If it is decided that the project could have a significant effect on its surroundings, the lead agency will produce an Environmental Impact Report (EIR). This document typically takes over a year to produce and outlines the potential effects of the project, measures to mitigate these impacts, and analysis of project alternatives.

Expedited CEQA review process

Instead of a potentially lengthy environmental review process, a lead agency and developer can work together to reduce the environmental impacts of a project to a less than significant level.

The lead agency will outline these revisions agreed upon by the developer in a Mitigated Negative Declaration (MND), which is posted online alongside the IS that is then subject to a public comment period.

If the lead agency doesn’t receive any comments containing evidence of the project having a potentially significant impact, it will issue an ND approving construction of the project, which was filed by the City of Carson for Arevon’s Avocet project on August 6 2024.

The City of Carson concluded the project would have a ‘less than significant impact’ on the surrounding area, with mitigation measures in place.

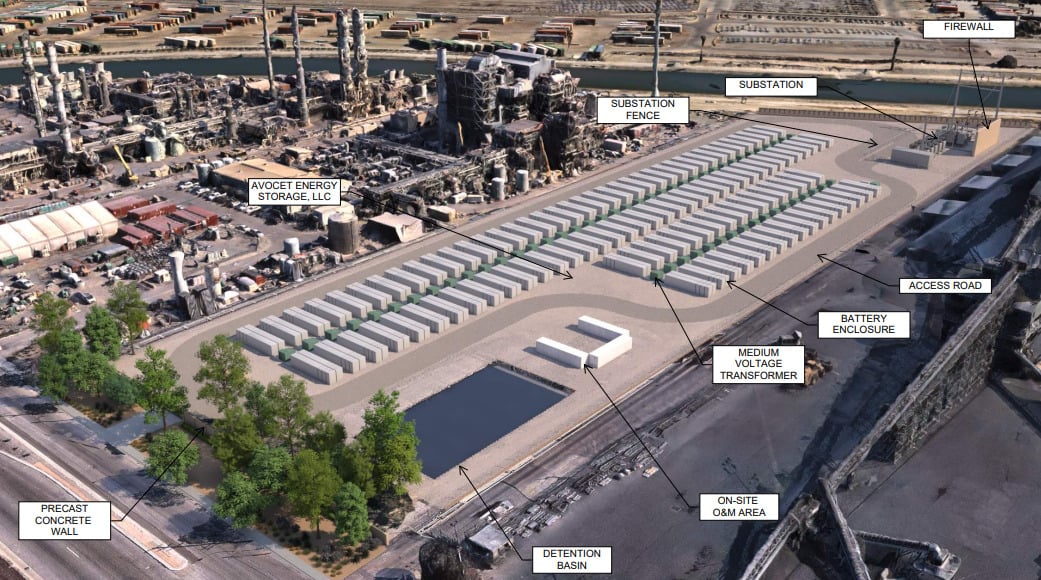

The project will be located between an industrial gas facility from Air Products and a petroleum coke handling facility from Marathon, as shown in the render at the top of this article.

200MW/800MWh connecting to the CAISO grid

The IS and MND report describe the Avocet Energy Storage project as a 200MW/800MWh standalone BESS located at 23320 Alameda Street in the City of Carson, California.

Interconnection to the California Independent System Operator (CAISO) grid will be via Southern California Edison’s (SCE’s) Hinson 230kV substation through a single gen-tie line.

Arevon has already secured an interconnection agreement for the project with CAISO and SCE that was processed as part of the California system operator’s Cluster 12 process (queue no. 1608).

The IS and MND report outlining further project information can be found here, with mitigation measures found on page 151-160: Chapter 4 – Mitigation Monitoring and Reporting Program.

Battery supply agreement and power offtaker secured

The Avocet project is one of Arevon’s most developed pipeline projects, with the developer having also secured a battery supply agreement with Tesla along with a power offtake agreement with California community choice aggregator (CCA) San Diego Community Power (SDCP).

Under the terms of a 15-year energy storage services agreement (ESSA), SDCP will pay Arevon a fixed price for capacity—adjusted for availability and verified capacity—commencing 15 April 2026.

The agreement was unanimously approved by SDCP’s Board of Directors at a regular meeting held on 16 November 2023. The agenda packet containing further details on the agreement can be found here.

Arevon also disclosed in a recent press release that Tesla would be supplying its Megapacks for the project.

Extensive California BESS portfolio

Arevon has an extensive BESS portfolio in California at various stages of development, including its 200MW/800MWh Condor Storage facility located in San Bernardino County that was recently cleared for commercial operations, as reported by Energy.Storage-News last week.

It also includes a larger 300MW/1,200MWh BESS located in San Diego County known as the Nighthawk Storage facility, which is under construction according to the developer’s website.

Arevon has secured a 15-year resource adequacy agreement for power offtake from the project with California utility Pacific Gas & Electric (PG&E).

Arizona: Tucson Electric Power to build second 200MW/800MWh BESS project

The two BESS projects will be the largest in TEP’s portfolio and among the largest in the state, and will help TEP manage supply and demand in the state. They will be built alongside each other next to a TEP substation near Tucson, the capital of Arizona.

“Our new Roadrunner Reserve II system will help us make the most of intermittent resources, especially during the summer when usage is highest and customers are counting on us the most,” said Susan Gray, TEP’s President and CEO. “We need additional energy storage as part of a diverse energy portfolio to support service reliability.”

Both projects will be built by engineering, procurement and construction (EPC) firm DEPCOM using lithium iron phosphate-based (LFP) BESS units. DEPCOM’s VP of energy storage business development discussed its approach to building Roadrunner Reserve in an interview with Energy-Storage.news recently (Premium access), including combining EPC with operations and maintenance (O&M).

TEP, a utility operating solely in Arizona, has 50MW of operational BESS today, including the 30MW unit at the Wilmot Energy System, pictured above.

The Roadrunner Reserve projects, which will quintuple that capacity, are in line with the utility’s 2023 Integrated Resource Plan (IRP), part of its roadmap to achieving net zero direct greenhouse gas (GHG) emissions by 2050.

It will also procure the power from the Winchester Solar project, which combines 80MW of solar and an 80MW BESS, from developer-operator Torch Clean Energy when it comes online in 2027.

Roadrunner Reserve II was selected through the utility’s 2024 all-source request for proposals (ASRFP) process, which sought 825MW of ‘firm capacity’ alongside 625MW of renewables. TEP and sister firm UniSource Energy Services are evaluating other proposals submitted for the ASRFP.

Utilities are driving the grid-scale BESS market in Arizona, either by building the projects themselves, like TEP, or procuring their power under long-term tolling agreements. Salt River Project (SRP) and Arizona Public Service (APS) recently secured power via tolls from 1,000MWh and 600MWh BESS projects, respectively. California-based utilities are doing the same for projects across the state line, including PG&E.

‘Lacking information’: Chile regulator kicks back Colbun’s 800MW pumped hydro project environmental review

Colbun submitted its environmental impact study (EIS) in June 2024, but earlier this week (12 August), the Environmental Assessment Service (SEA) for Antofagasta issued an ‘early termination notice’.

Its notice said information was missing, which would not allow the assessment to proceed in the appropriate manner. The missing information, the service said, meant it couldn’t rule out whether it would have a significant impact on local flora and fauna as well as human populations that are part of the indigenous peoples of Paposo.

One specific issue was the lack of consideration for how the construction of a cable car related to the project would affect wildlife on the cliff face.

It also omitted to mention that two groups of indigenous communities belonging to the Chango People live less than 500m from the site.

Of the eight communities that were addressed in Colbun’s EIS, the resolution found that three said the project would not affect them while five said the construction would limit their movement and obstruct their ability to collect coastal plants for medicinal uses and graze cattle.

In a Spanish-language press release published on BNAmericas two days after the early termination notice, Colbun said it disagreed with the reasons given by the Antofagasta SEA for doing so.

The Paposo project would entail US$1.4 billion of investment. The overall energy storage capacity of the project hasn’t been revealed, but PHES technology would typically have a discharge duration of 6-20 hours, meaning anywhere from 4.8GWh to 16GWh in this case.

Colbun is also deploying battery energy storage systems (BESS) in Chile, with the first of some 800MW coming online in late 2022.

In a related development, Colbun entered into a memorandum of understanding (MOU) with high-density PHES technology company RheEnergise last year to explore the potential of a smaller system in Chile using RheEnergise’s technology.

You can read the Spanish-language EIA documents from the Chilean government pertaining to the Paposo project here. See a Spanish-language video render of the project from Colbun on Youtube below.

[embedded content]

Energy-Storage.news’ publisher Solar Media will host the 3rd annual Energy Storage Summit Latin America in Santiago, Chile, 15-16 October 2024. This year’s event brings together Latin America’s leading investors, policymakers, developers, utilities, network operators, EPCs and more all in one place to discuss the landscape of energy storage in the region. Visit the official site for more info.

Continue readingVIDEO: Empowering Australia’s battery energy storage assets through market participation

GridBeyond’s solar, storage and EV regional director Stace Tzamtzidis and Balancia Consulting strategy consultant Peter Newland were in conversation with Energy-Storage.news editor Andy Colthorpe.

Tzamtzidis discussed building a business case for battery storage from various angles. Those included technical performance and reliability, evolving market dynamics and volatility, regulatory and environmental considerations, market access, forecasting and modelling and operational flexibility.

The firm’s solutions include battery storage design software, a forecaster application, a bid optimiser application and a machine learning price forecaster. Tzamtzidis went through each of these and how they can be applied to battery storage to maximise performance.

That was preceded by a data-driven look at the market across utility-scale, commercial & industrial (C&I) and residential segments in Australia from Peter Newland, strategy consultant, Balancia Consulting.

Speakers:

Stace Tzamtzidis, solar, storage and EV regional director, GridBeyond

Peter Newland, strategy consultant, Balancia Consulting

[embedded content]

You can also register to watch the webinar from the on-demand section of the site, which will also enable you to access the presentation slide deck, and where you can find all our other Energy-Storage.news webinars.