Lithium-ion battery cells typically degrade – lose their energy storage capacity – by 10-20% in the first five years of operation which is then offset by adding new units to maintain capacity, otherwise known as augmentation. If true, the breakthrough has huge ramifications for energy storage applications and the technology’s cost-effectiveness.

CATL applying zero-degradation technology after three-year demonstration

In a product launch ceremony video posted on YouTube since then (on 18 April), the firm’s energy storage division CTO, Dr Jinmei Xu, explained that it had applied technological learnings from an R&D project into a zero-degradation BESS started in 2016.

In 2020, it made a ‘major technological breakthrough’ in BESS by achieving ‘zero degradation’ over three years using lithium iron phosphate (LFP) battery cells on the Jinjiang Project in Fujian province. It had an annual utilisation rate of 98%, and none of the battery cells were ever replaced during the operation.

The word CATL used was shuāi jiǎn (衰減), which directly translates as either degradation or attenuation, with the latter used in the ceremony’s translation and the former used in English-language press releases.

“We’ve strived hard to explore the technologies to achieve zero attenuation. However it takes a giant leap forward to put lab technologies into practice,” Dr Xu said in the ceremony.

“I’m proud to announce that we have made it to reach mass production of the five-year zero attenuation product. It is a milestone in the long-life lithium battery technology development.”

CATL is being tight-lipped on how it has achieved zero degradation, only mentioning the use of biomimetic SEI (solid electrolyte interphase) and self-assembled electrolyte technologies. Others have posited that ‘lithium compensation technology’ or ‘pre-lithiation’, where additives gradually release extra lithium in the first operational cycles, could help achieve such a breakthrough.

Clever marketing, adaptive BMS or technological breakthrough?

The five-year zero degradation claim has been met with both scepticism and awe from the energy storage industry, with many taking to business networking site LinkedIn to comment on the claim.

Many have praised the company and pointed out that as the world’s largest lithium-ion battery firm and one with a track record for technology breakthroughs, its claim should be taken seriously, while others have poured cold water on it.

Dave West, CEO of Australia-based battery procurement platform BatNav, said: “It’s clever marketing, but no cell has zero degradation. You either oversize or augment your battery. Either way, the customer pays.”

Several have speculated that the Tener product is, therefore, most likely a 7.5-8MWh system marketed as a 6.25MWh one, including Drew Lebowitz, managing director of Oregon-based energy storage design and advisory firm PowerSwitch, and Konsta Anttila, an asset manager engineer for US system integrator FlexGen.

However, others have pointed out that such an energy-dense system would be very heavy and could present logistical challenges for delivery and deployment.

Dr. Kai-Philipp Kairies, CEO of battery analytics firm Accure Battery Intelligence, offered an alternative postulation as to how CATL had achieved it.

“So what about the “5 year without degradation” promise: Has CATL cracked the battery ageing code?,” Kairies wrote.

“The simple answer is “no”. They probably use an adaptive BMS (battery management system) that gradually opens up the upper voltage limits to compensate the occurring ageing. Over 5 years that should be anything between 5 and 12 percent of the system’s overall capacity. Owner are advised to regularly track if the system fulfills its contractual capacity obligations, since BMS are typically not very accurate.”

Andreas Fornwald, former CEO of energy management software solution provider Doosan Gridtech, was upbeat, saying he “…witnessed the product in person and can confirm that this one is real, moreover CATL is just a year or so ahead of many other battery cell manufacturers.”

“I am convinced that by the end of this year, we will see similar BESS containers coming from all major competitors, [just as] it happened last year with the 5MWh container and three years ago with the 3.4MWh container. The race is far from over, and I bet that in two to three years, we will see the 10MWh container with a 10-year zero-degradation system.”

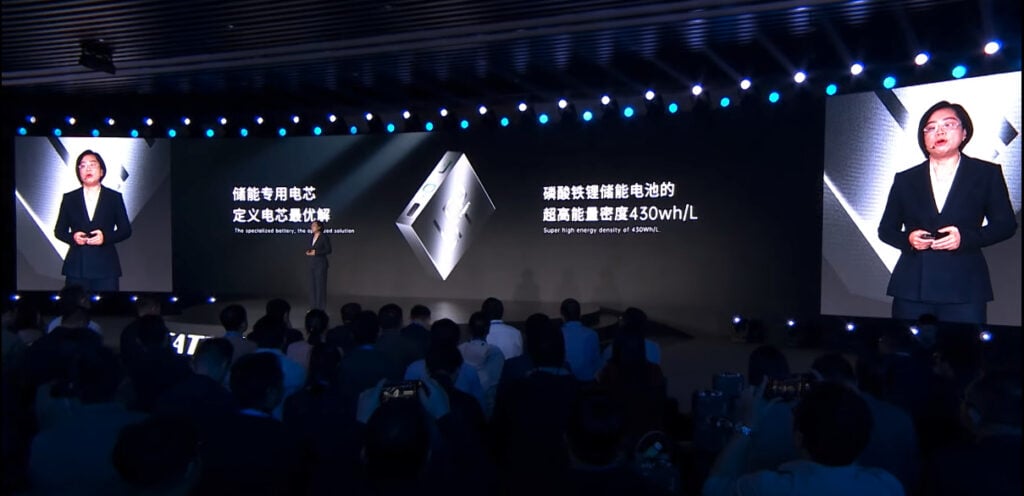

CATL revealed in the presentation that the Tener product is equipped with the ‘L long-line battery’ specialised for energy storage, which has an energy density of 430Wh/L. This battery is pictured below.

Energy density

The energy density aspect of Tener, at 6.25MWh per 20-foot container, has also garnered praise, although it may not be the highest in the industry. EV giant BYD, Tesla’s main Chinese competitor, has teased a 6.432MWh product, while Svolt Energy is reportedly launching a 6.7MWh product of the same size.

The move beyond 5MWh, which for a long time appeared to be the industry-leading standard adopted by most China-based companies, has partially been made possible by a redesign of the battery cell composition itself.

As explained by engineering and advisory firm Clean Energy Associates (CEA) in a guest blog last week, lithium-ion batteries have started to move from a ‘jelly roll’ stack design to a ‘Z-stack’ design which offers a 10% volumetric energy density improvement.

Energy-Storage.news’ publisher Solar Media will host the 2nd Energy Storage Summit Asia, 9-10 July 2024 in Singapore. The event will help give clarity on this nascent yet quickly growing market, bringing together a community of credible independent generators, policymakers, banks, funds, off-takers and technology providers. For more information, go to the website.